U.S. Department of the Interior

U.S. Geological Survey

Techniques and Methods 3

-

A19

Levels at Gaging Stations

Chapter 19 of

Section A, Surface-Water Techniques

Book 3, Applications of Hydraulics

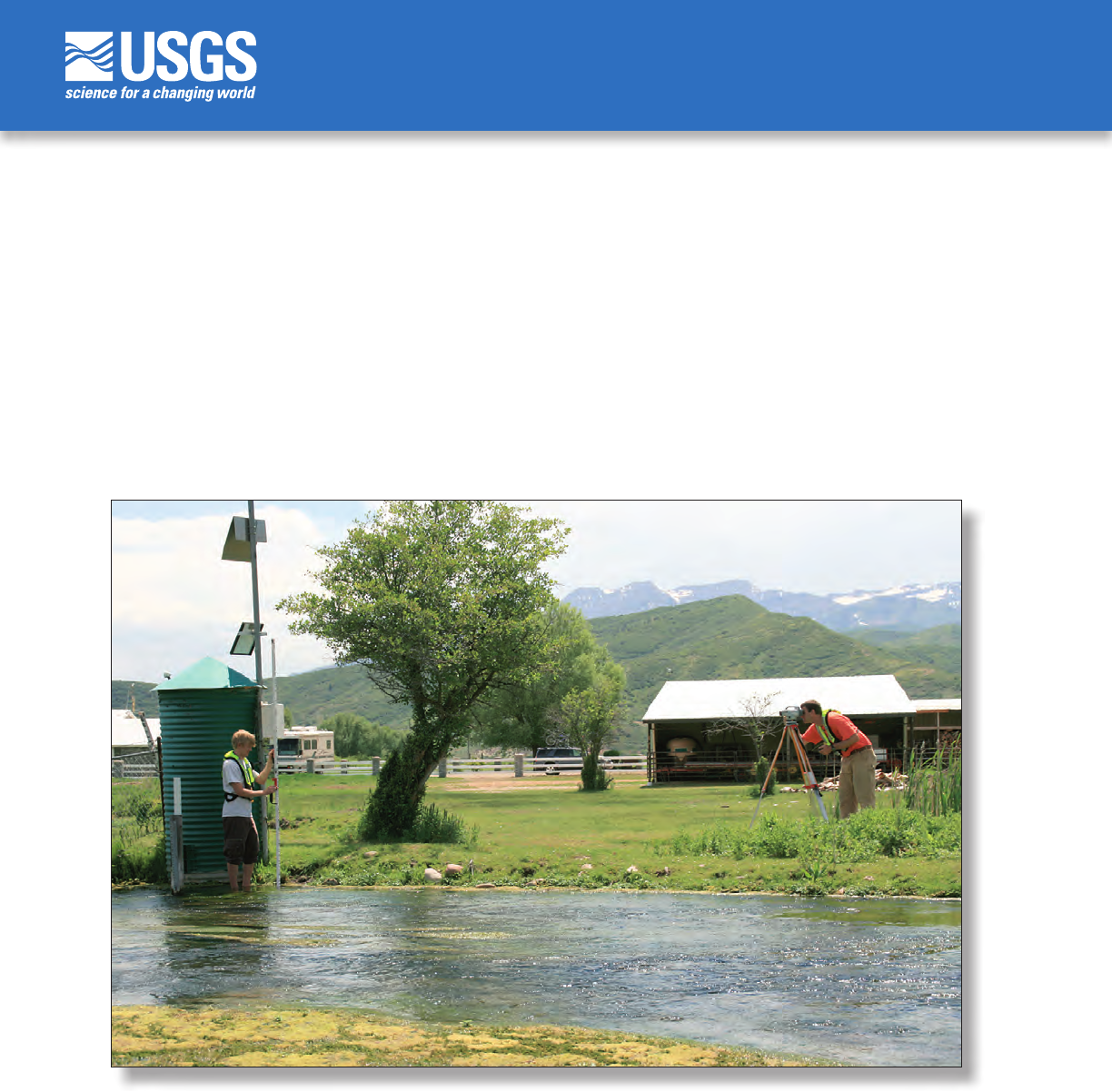

Cover: View of levels being run at U.S. Geological Survey streamflow-gaging

station 10156000, Snake Creek near Charleston, Utah.

Photograph taken by K. Michael Nolan, U.S. Geological Survey, June 30, 2010.

Back Cover: USGS topographic field party, circa 1925, with a Wye level on a

tripod and two stadia rods. Photograph by U.S. Geological Survey.

Levels at Gaging Stations

By Terry A. Kenney

Chapter 19 of

Section A, Surface-Water Techniques

Book 3, Applications of Hydraulics

Techniques and Methods 3–A19

U.S. Department of the Interior

U.S. Geological Survey

U.S. Department of the Interior

KEN SALAZAR, Secretary

U.S. Geological Survey

Marcia K. McNutt, Director

U.S. Geological Survey, Reston, Virginia: 2010

For more information on the USGS—the Federal source for science about the Earth, its natural and living resources,

natural hazards, and the environment, visit http://www.usgs.gov or call 1-888-ASK-USGS

For an overview of USGS information products, including maps, imagery, and publications,

visit http://www.usgs.gov/pubprod

To order this and other USGS information products, visit http://store.usgs.gov

Any use of trade, product, or firm names is for descriptive purposes only and does not imply endorsement by the

U.S. Government.

Although this report is in the public domain, permission must be secured from the individual copyright owners to

reproduce any copyrighted materials contained within this report.

Suggested citation:

Kenney, T.A., 2010, Levels at gaging stations: U.S. Geological Survey Techniques and Methods 3-A19, 60 p.

iii

Preface

This series of manuals on techniques and methods (TM) describes approved scientific and data-

collection procedures and standard methods for planning and executing studies and laboratory

analyses. The material is grouped under major subject headings called “books” and further

subdivided into sections and chapters. Section A of book 3 is on surface-water techniques.

The unit of publication, the chapter, is limited to a narrow field of subject matter. These

publications are subject to revision because of experience in use or because of advancement

in knowledge, techniques, or equipment, and this format permits flexibility in revision and

publication as the need arises. Chapter A19 of book 3 (TM 3–A19) deals with levels at gaging

stations. The original version of this chapter was published in 1990 as U.S. Geological Survey

(USGS) Techniques of Water-Resources Investigations, chapter A19 of book 3. New and

improved equipment, as well as some procedural changes, have resulted in this revised second

edition of “Levels at gaging stations.”

This edition supersedes USGS Techniques of Water-Resources Investigations 3A–19, 1990,

“Levels at streamflow gaging stations,” by E.J. Kennedy.

This revised second edition of “Levels at gaging stations” is published on the World Wide Web

at http://pubs.usgs.gov/tm/tm3A19/ and is for sale by the U.S. Geological Survey, Science

Information Delivery, Box 25286, Federal Center, Denver, CO 80225.

iv

This page intentionally left blank.

v

Contents

Preface ...........................................................................................................................................................iii

Abstract ...........................................................................................................................................................1

Introduction.....................................................................................................................................................1

Purpose and Scope .......................................................................................................................................1

Differential Leveling and Leveling Equipment ..........................................................................................2

Level Instruments..................................................................................................................................2

Optical Levels ...............................................................................................................................3

Electronic Digital Levels .............................................................................................................3

Parallax ..........................................................................................................................................4

Checking the Engineer’s Level ...........................................................................................................4

Fixed-Scale Test ..........................................................................................................................6

Peg Test .........................................................................................................................................6

Manufacturer-Recommended Collimation Test ......................................................................7

Collimation Error and Balanced Sightline Distances .....................................................................8

Leveling Rods.........................................................................................................................................9

Inspection of Leveling rod .......................................................................................................10

Proper Care and Use of a Rod Level .......................................................................................11

Correcting for Rod Scale Expansion or Contraction Due to Temperature Variations ....11

Considerations for Secondary Devices Used for Vertical Measurements ......................13

Establishment of Gage Datum ...................................................................................................................13

Installation of Reference Marks .......................................................................................................14

Referencing a Gage Datum to an Established Datum ..................................................................16

Frequency of Gaging-Station Levels ........................................................................................................17

Preparation for Running Levels .................................................................................................................18

Determining the Need for Levels .....................................................................................................18

Compiling Historic Level Notes and Site Sketch Maps ................................................................19

Considerations for Site Conditions ..................................................................................................19

Running Levels ............................................................................................................................................19

Standards and Requirements for Gaging-Station Levels ....................................................20

Circuit-Closure Error ................................................................................................................20

Assessing a Level Circuit and Adjusting Elevations .....................................................................25

Methods for Taking Foresights on Gages and the Water Surface .............................................27

Vertical Staff Gage ....................................................................................................................27

Electric Tape Gage .....................................................................................................................27

Wire-Weight Gage .....................................................................................................................30

Crest-Stage Gage ......................................................................................................................32

Inclined Staff Gage ....................................................................................................................33

Water Surface ............................................................................................................................36

Resetting Gages Based on the Results of Levels ..........................................................................36

Methods for Simplifying Complex Level Circuits ...........................................................................36

Separating Complex Level Circuits into a Set of Sequentially Closed Simple

Level Circuits ................................................................................................................37

vi

Running Levels—Continued

......................................................................................................................19

Methods for Simplifying Complex Level Circuits—Continued ....................................................36

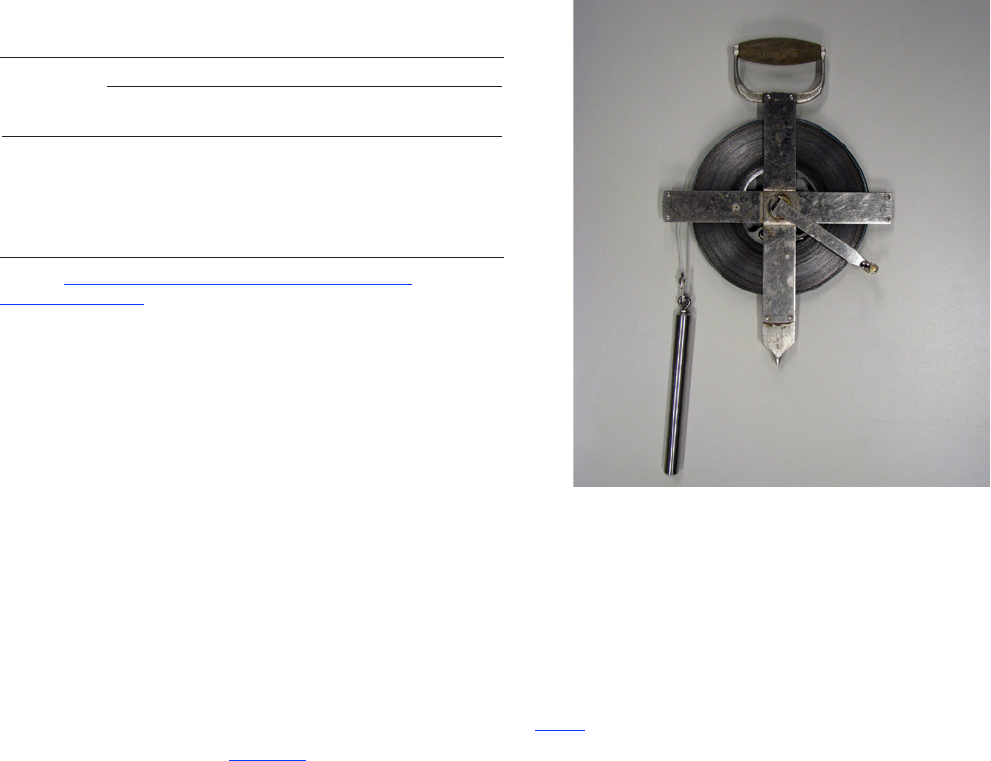

Using a Suspended Weighted Steel Tape to Carry Elevation to or from a Bridge

Structure .......................................................................................................................39

Bridge-Down Method .....................................................................................................44

Ground-Up Method ..........................................................................................................44

Office Procedures .......................................................................................................................................45

Applying Datum Corrections to Gage Height Time Series ..........................................................45

Developing a Site-Specific Historical Level Summary .................................................................45

Developing a Site Sketch Map .........................................................................................................45

Auxiliary Data to be Obtained During Level Runs ..................................................................................46

Summary........................................................................................................................................................46

References Cited..........................................................................................................................................46

Glossary .........................................................................................................................................................49

Appendix A. Fixed-Scale Test Form .......................................................................................................51

Appendix B. Peg Test Form ....................................................................................................................53

Appendix C. Level Notes Form ...............................................................................................................55

Appendix D. Historical Level Summary Form ......................................................................................57

Appendix E. Summary of Selected Requirements and Tolerances for Gaging Station Levels ....59

Contents—Continued

Figures

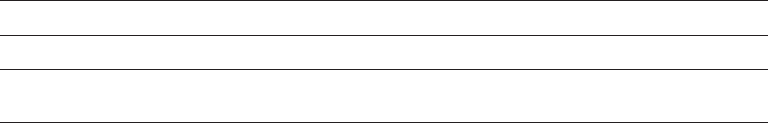

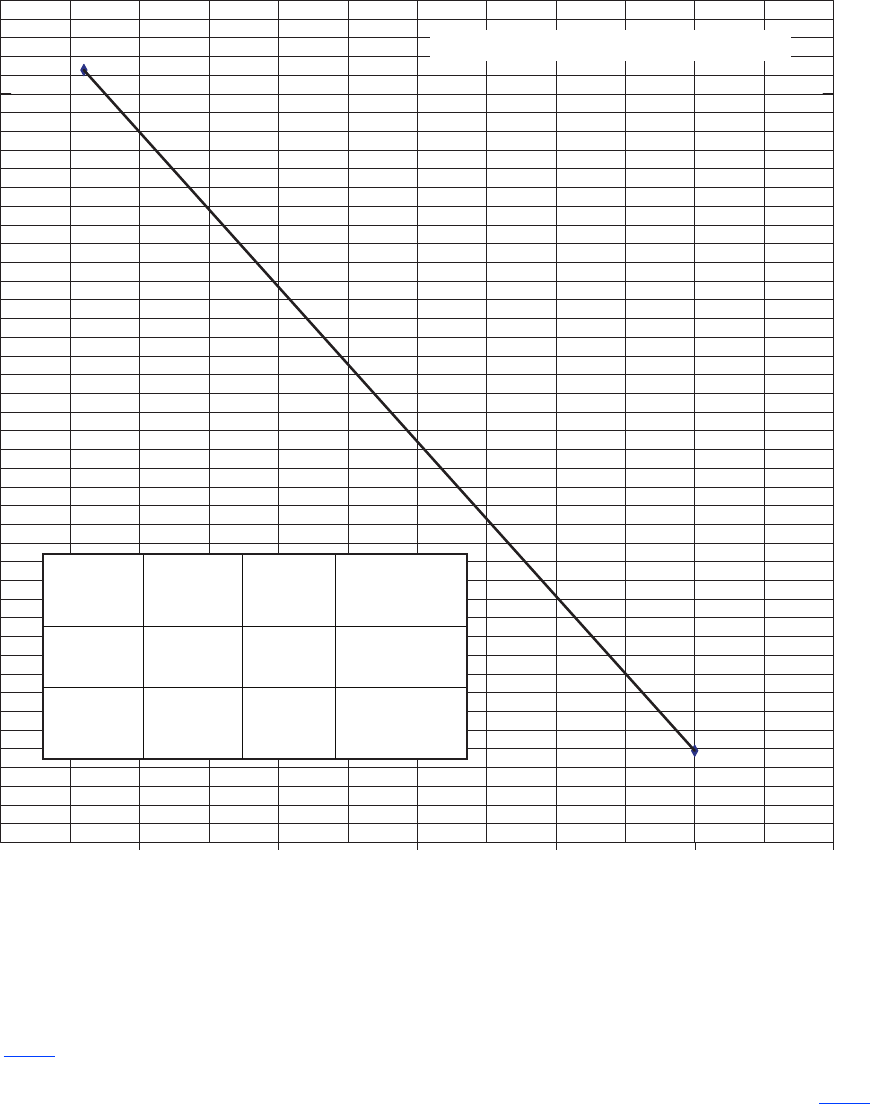

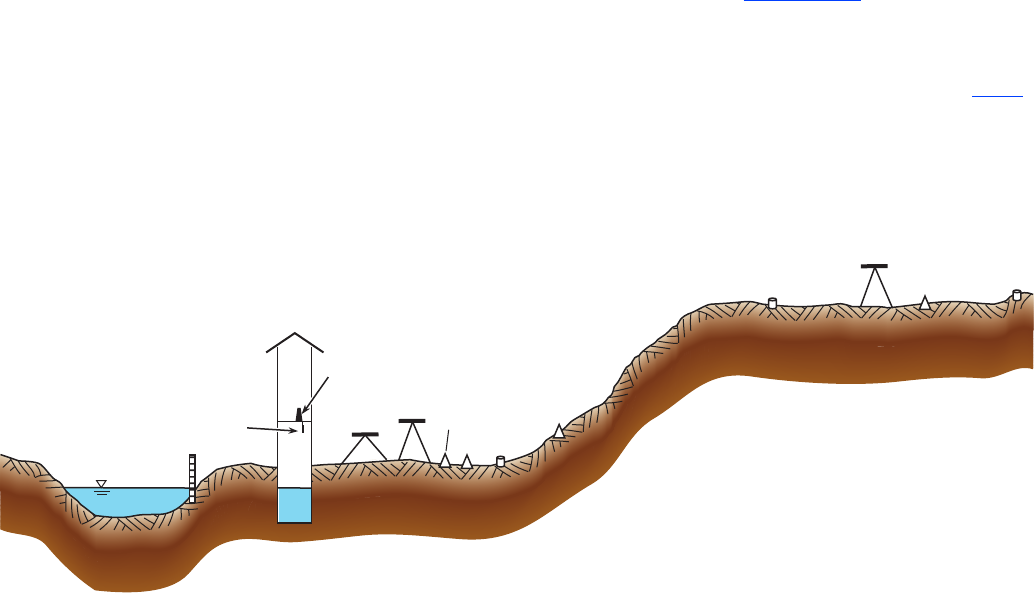

Figure 1. Diagram of differential leveling using an engineer’s level and leveling rods ……… 2

Figure 2. Photographs of optical levels …………………………………………………… 3

Figure 3. Photographs of electronic digital levels ………………………………………… 4

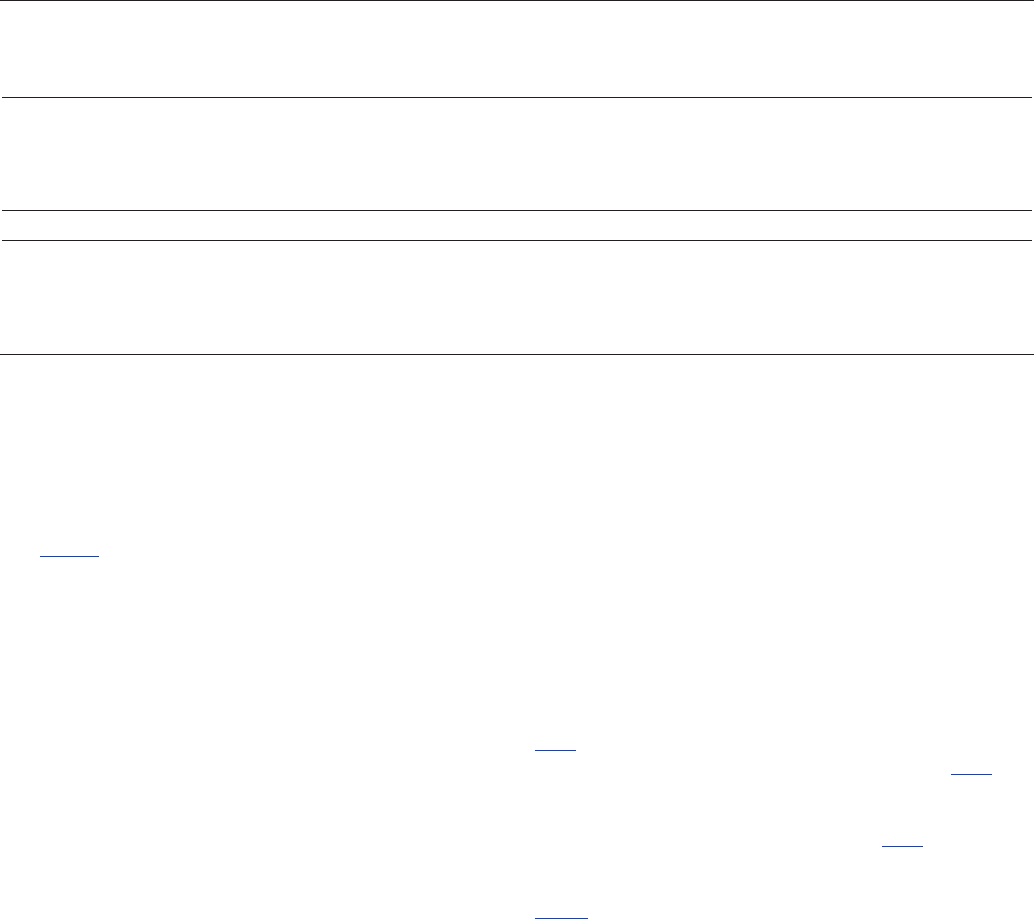

Figure 4. Photographs of bar-code leveling rods …………………………………………… 5

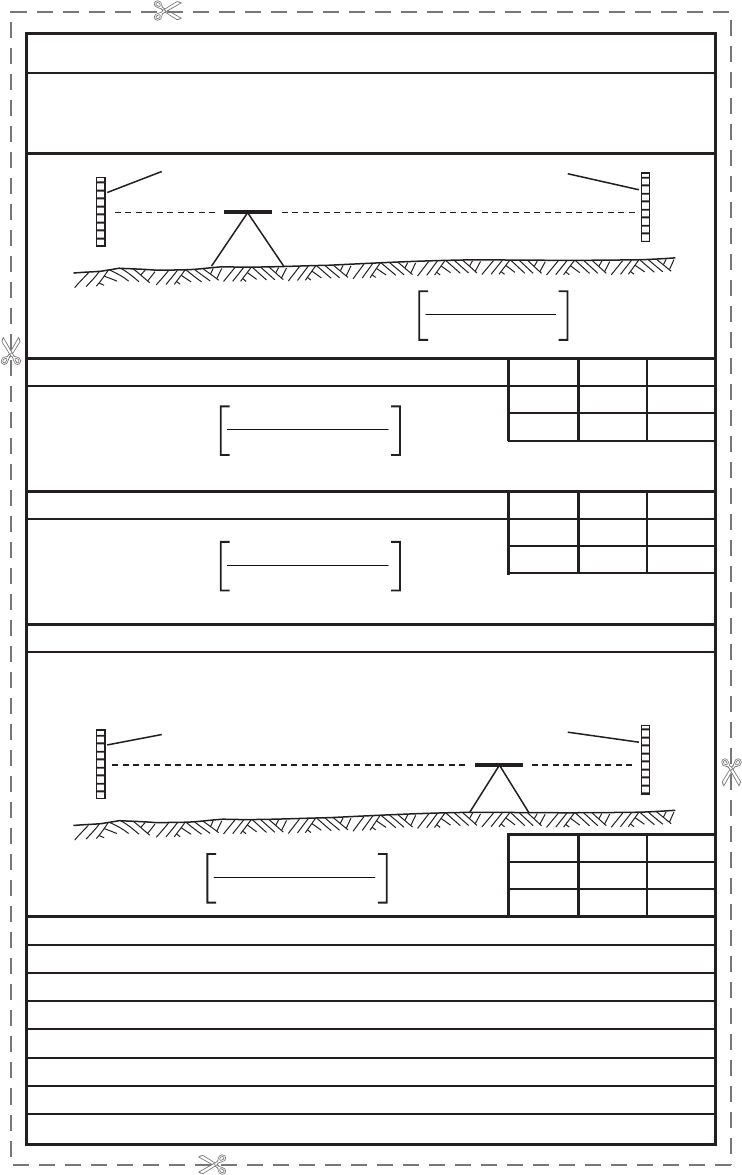

Figure 5. Diagram of an engineer’s level and rod scales set up for the fixed-scale test …… 7

Figure 6. Diagram of an engineer’s level and leveling rods set up for the two-peg test …… 7

Figure 7. Photographs of self-reading leveling rods ………………………………………… 10

Figure 8. Scale of a self-reading Philadelphia rod ………………………………………… 11

Figure 9. Photographs of stand-alone and permanently attached rod levels ……………… 12

Figure 10. Photograph of a steel tape with 1 pound of tension ……………………………… 13

Figure 11. Diagram of gage datum at a station ……………………………………………… 14

Figure 12. Typical reference marks ………………………………………………………… 15

Figure 13. Extreme depth of frost map ……………………………………………………… 16

Figure 14. Decision tree for determining if levels are needed ……………………………… 17

Figure 15. Complete set of level notes for a level circuit with two instrument setups ……… 21

Figure 16. Complete set of level notes for a level circuit with eight instrument setups ……… 23

Figure 17. Photographs of foresights being taken on staff plates by holding leveling rods

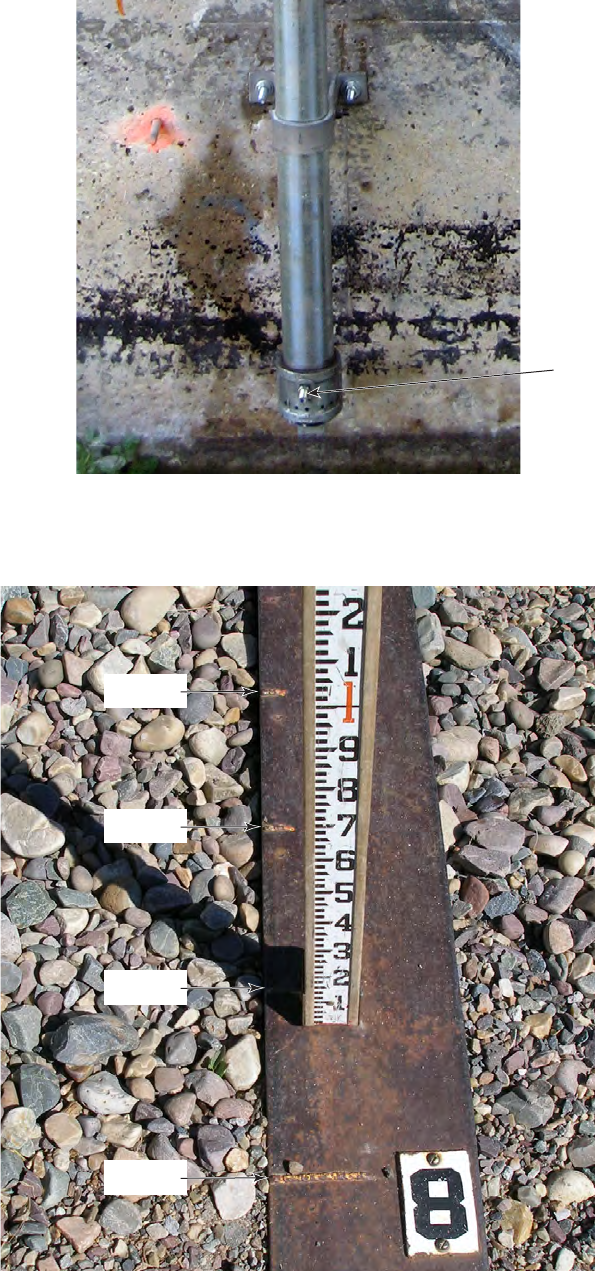

on nails driven into backing boards ……………………………………………… 28

Figure 18. Picture of an electric tape gage with a pocket rod held on a stack of coins at

the elevation of the index ………………………………………………………… 29

Figure 19. Photographs of a wire-weight gages mounted on bridges ……………………… 31

vii

Conversion Factors

Multiply By To obtain

Length

inch (in.) 2.54 centimeter (cm)

foot (ft) 0.3048 meter (m)

Temperature in degrees Fahrenheit (°F) may be converted to degrees Celsius (°C) as follows:

°C = (°F - 32)/1.8

Figure 20. Photograph of a cantilevered wire-weight gage located to the left of a

stilling well ………………………………………………………………………… 32

Figure 21. Stage-related wire-weight corrections determined from levels ………………… 33

Figure 22. Photograph of a crest-stage gage where the index is the bottom cap …………… 34

Figure 23. Photograph of a crest-stage gage where the index is a bolt installed through

the pipe …………………………………………………………………………… 35

Figure 24. Photograph of an inclined staff gage installed on a streambank ………………… 35

Figure 25. Leveling diagram showing objective points in a complex circuit and level notes

for a complex leveling circuit …………………………………………………… 37

Figure 26. Leveling diagram and level notes showing 3 simple level circuits used to

replace 1 complex level circuit …………………………………………………… 39

Figure 27. Leveling diagram and level notes illustrating the use of a suspended steel tape

to carry elevations from a bridge down to a streamside gage location and from

a streamside gage location up to a bridge ……………………………………… 41

Figures—Continued

Tables

Table 1. Notes for gaging station levels run when all sightline distances are equal and

the instrument used has a collimation error of 0.01 foot per 100 feet …………… 9

Table 2. Notes for gaging station levels run when sightline distances between the

instrument and objects vary in the same order for two setups and the

instrument used has a collimation error of 0.01 foot per 100 feet ………………… 10

Table 3. Notes for gaging station levels run when sightline distances between the

instrument and objects vary inversely for two setups and the instrument used

has a collimation error of 0.01 foot per 100 feet …………………………………… 11

Table 4. Approximate coefficients of thermal expansion for common leveling rod-scale

materials ………………………………………………………………………… 15

Table 5. Requirements for demonstrating gaging station stability ………………………… 21

Table 6. Example summary of levels where the stability criterion is not met ……………… 21

Table 7. Standards and select requirements for leveling ………………………………… 28

Table 8. Standards and adopted requirements for gaging station levels ………………… 28

Table 9. Computed adjustment values for each instrument setup of a four-instrument

level circuit with a closure error of –0.005 foot …………………………………… 30

Table 10. Technique for rounding off numbers ……………………………………………… 30

viii

This page intentionally left blank.

Abstract

Operational procedures at U.S. Geological Survey gaging

stations include periodic leveling checks to ensure that gages

are accurately set to the established gage datum. Differential

leveling techniques are used to determine elevations for

reference marks, reference points, all gages, and the water

surface. The techniques presented in this manual provide

guidance on instruments and methods that ensure gaging-

station levels are run to both a high precision and accuracy.

Levels are run at gaging stations whenever differences in gage

readings are unresolved, stations may have been damaged, or

according to a pre-determined frequency. Engineer’s levels,

both optical levels and electronic digital levels, are commonly

used for gaging-station levels. Collimation tests should be

run at least once a week for any week that levels are run, and

the absolute value of the collimation error cannot exceed

0.003 foot/100 feet (ft).

An acceptable set of gaging-station levels consists of a

minimum of two foresights, each from a different instrument

height, taken on at least two independent reference marks, all

reference points, all gages, and the water surface. The initial

instrument height is determined from another independent

reference mark, known as the origin, or base reference mark.

The absolute value of the closure error of a leveling circuit

must be less than or equal to

0.003 n

ft, where n is the total

number of instrument setups, and may not exceed |0.015| ft

regardless of the number of instrument setups. Closure error

for a leveling circuit is distributed by instrument setup and

adjusted elevations are determined. Side shots in a level

circuit are assessed by examining the differences between the

adjusted rst and second elevations for each objective point

in the circuit. The absolute value of these differences must be

less than or equal to 0.005 ft. Final elevations for objective

points are determined by averaging the valid adjusted rst and

second elevations. If nal elevations indicate that the reference

gage is off by |0.015| ft or more, it must be reset.

Introduction

At gaging stations where water-surface elevation or

stage is measured, the U.S. Geological Survey (USGS) sets

gages to read the stage above a specied reference surface

called the gage datum (Kennedy, 1990). Equipment in most

gaging stations measures and records stage at a frequency

of 15 minutes. At streamow gaging stations, discrete

measurements of streamow, made by hydrographers, are

paired with a representative stage value. Over time, these

pairings dene a site-specic stage-discharge relation to

which recorded stage values are applied to obtain a continuous

streamow record. To provide accurate and relevant data, it is

imperative that gages agree with the established gage datum

for the life of the station. To check and ensure that gages are

properly set to gage datum, differential leveling techniques are

used. Levels are run at gaging stations according to a standard

set of frequency requirements, when unresolved gage reading

differences have been identied, or when the station has been

damaged.

Purpose and Scope

The purpose of this manual is to document the

procedures that should be followed when running levels

to check that gages are set to the established gage datum.

Leveling equipment is discussed, along with specic precision

requirements, desired accuracy, and calibration requirements.

The required frequency for running gaging-station levels is

outlined and presented in an easy to follow decision tree. The

procedure for running levels at gaging stations is described

in detail and illustrated in example level circuits. Specic

error tolerances for both circuit closure and objective-point

elevation differences are presented. Methods for taking

foresights to various types of gages are discussed, and nally,

ofce procedures associated with gaging-station levels are

outlined. This manual describes new procedures for running

levels at gaging stations that supersede those described by the

previous USGS Techniques of Water-Resources Investigations

Report “Levels at Streamow Gaging Stations” by E.J.

Kennedy (1990).

Levels at Gaging Stations

By Terry A. Kenney

2 Levels at Gaging Stations

Differential Leveling and Leveling

Equipment

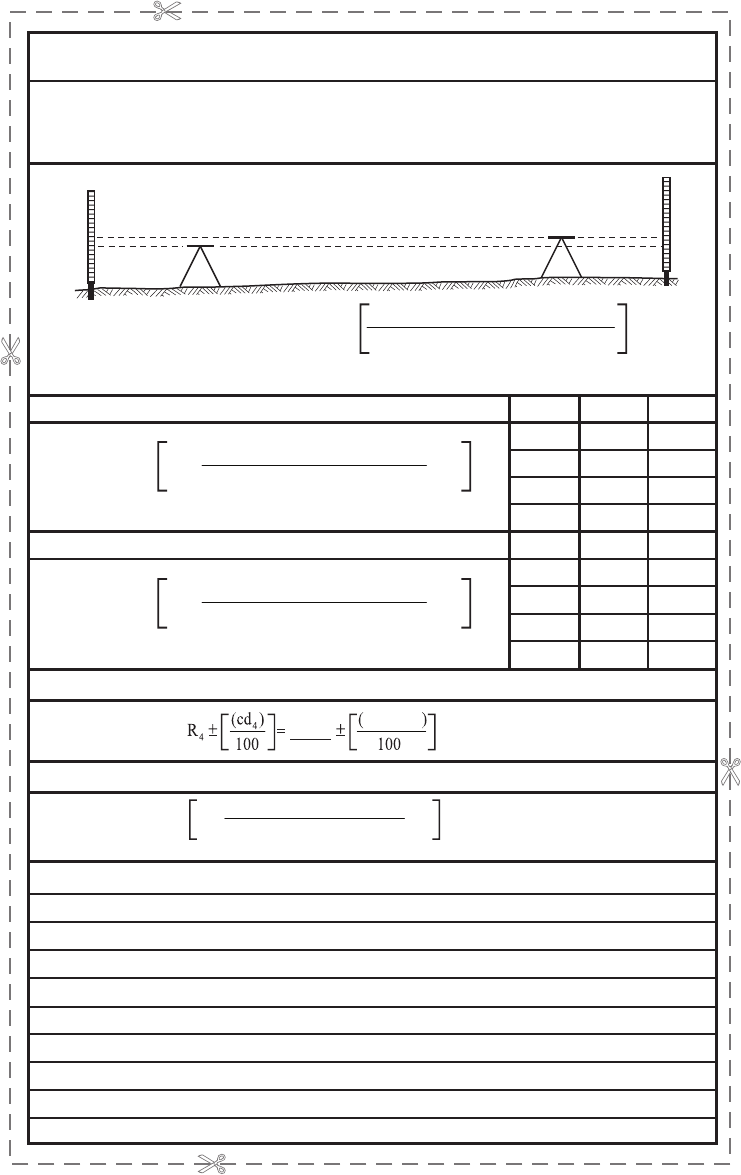

Differential leveling is the process of measuring the

vertical difference between a point of unknown elevation and

a point of known elevation (McCormac, 1983). By measuring

this difference, an elevation can be determined for the point

of unknown elevation. At gaging stations, this measurement

is most commonly made using an engineer’s level and a

calibrated leveling rod (g. 1). The engineer’s level is set up

about equidistant from the point of known elevation and the

point(s) of unknown elevation. A shot from the engineer’s

level is rst made to a leveling rod that is held on the known

elevation point. This reading on the leveling rod is called

a backsight (BS). The BS, which is the vertical distance of

the engineer’s level above this point, is added to the known

elevation of that point to determine the elevation of the

engineer’s level, or the height of the instrument. Shots are then

made from the engineer’s level to the leveling rod that is held

on point(s) of unknown elevation. These readings are called

foresights. A foresight (FS) is the distance of the engineer’s

level above the point and is subtracted from the instrument

height to determine elevation.

Differential leveling techniques are used at gaging

stations to determine elevations for reference marks, reference

points, gages, and the water surface. Reference marks are

objects (for example, brass tablets, steel rods, or bolts) that

are installed in the most stable locations near the gage and

are used to adjust the gages as necessary to keep them in

agreement with the gage datum (Kennedy, 1990). Reference

points are objects (for example, bolts, nails, or screws) that

are installed in locations to facilitate the determination of

gage heights by measuring their distance from the water

surface. A variety of engineer’s levels and leveling rods can be

used to run levels at streamow-gaging stations. The USGS

reports stage at most gaging stations in increments of 0.01 ft.

Therefore, gaging-station levels, which are used to verify

that gages agree with the gage datum, must be measured at

a higher level of precision and accuracy. Precision describes

the closeness of one measurement to another while accuracy

describes how close a given measurement is to the true value

(McCormac, 1983). The precision required of gaging-station

levels is 0.001 ft, while the desired accuracy is less than

0.010 ft. Instruments selected for running levels at gaging

stations must be capable of meeting these precision and

accuracy requirements.

Level Instruments

Many surveying instruments are available that have

several different equipment options and can perform

a variety of surveying tasks. Levels at gaging stations

require measurements of vertical distance and do not need

measurements of horizontal distance or horizontal angle.

Engineer’s levels are the most common instruments used for

running levels at gaging stations. Most engineer’s levels meet

the desired accuracy of less than 0.010 ft and the required

precision of 0.001 ft for gaging-station levels. Surveying

technology is continually changing, and other types of

surveying instruments, such as tilting instruments, may be

capable of meeting these accuracy and precision standards.

Point of

known elevation

Point of

unknown elevation

BS

BS Backsight

FS Foresight

FS

Leveling rod

Instrument

IP021599_Figure 1. Schematic of differential leveling.

EXPLANATION

Figure 1. Differential leveling using an engineer’s level and leveling rods.

Differential Leveling and Leveling Equipment 3

The techniques and methods presented in this manual provide

guidance on using engineer’s levels that ensures gaging-station

levels are run to a high level of precision and accuracy. Before

other types of surveying instruments are used for running

gaging-station levels, techniques and methods specic to those

instruments that ensure precision and accuracy requirements

are met must be rigorously documented. Engineer’s levels,

which are sometimes referred to as line or spirit levels, can

be classied in two general categories: optical levels and

electronic digital levels.

Optical Levels

Optical levels (g. 2) are used to manually read the

leveling rod that is held on an objective point. When using

an optical level, the operator reads the value off the rod at the

cross hair of the level. Self-reading rods used in gaging-station

levels are graduated to 0.01 ft. Precision requirements call

for the operator of an optical level to estimate measurements

within 0.001 ft. The ability to accurately estimate to 0.001 ft is

determined by the distance from the instrument to the rod, the

magnication power of the level’s optics, and environmental

conditions, such as the presence of heat waves. In general, the

magnication of optical levels is about 30 times and allows

readings as precise as 0.001 ft up to a distance of about 150 ft.

Most modern optical levels are automatic, or self-leveling

— the instrument levels itself precisely after being leveled

manually with its circular (bull’s eye) level (Kennedy, 1990).

Many older optical levels, such as the Dumpy level, are not

self-leveling and are time-consuming to set up and level.

These older instruments are also easily knocked out of level,

which can introduce unquantied errors into the leveling

circuit.

Electronic Digital Levels

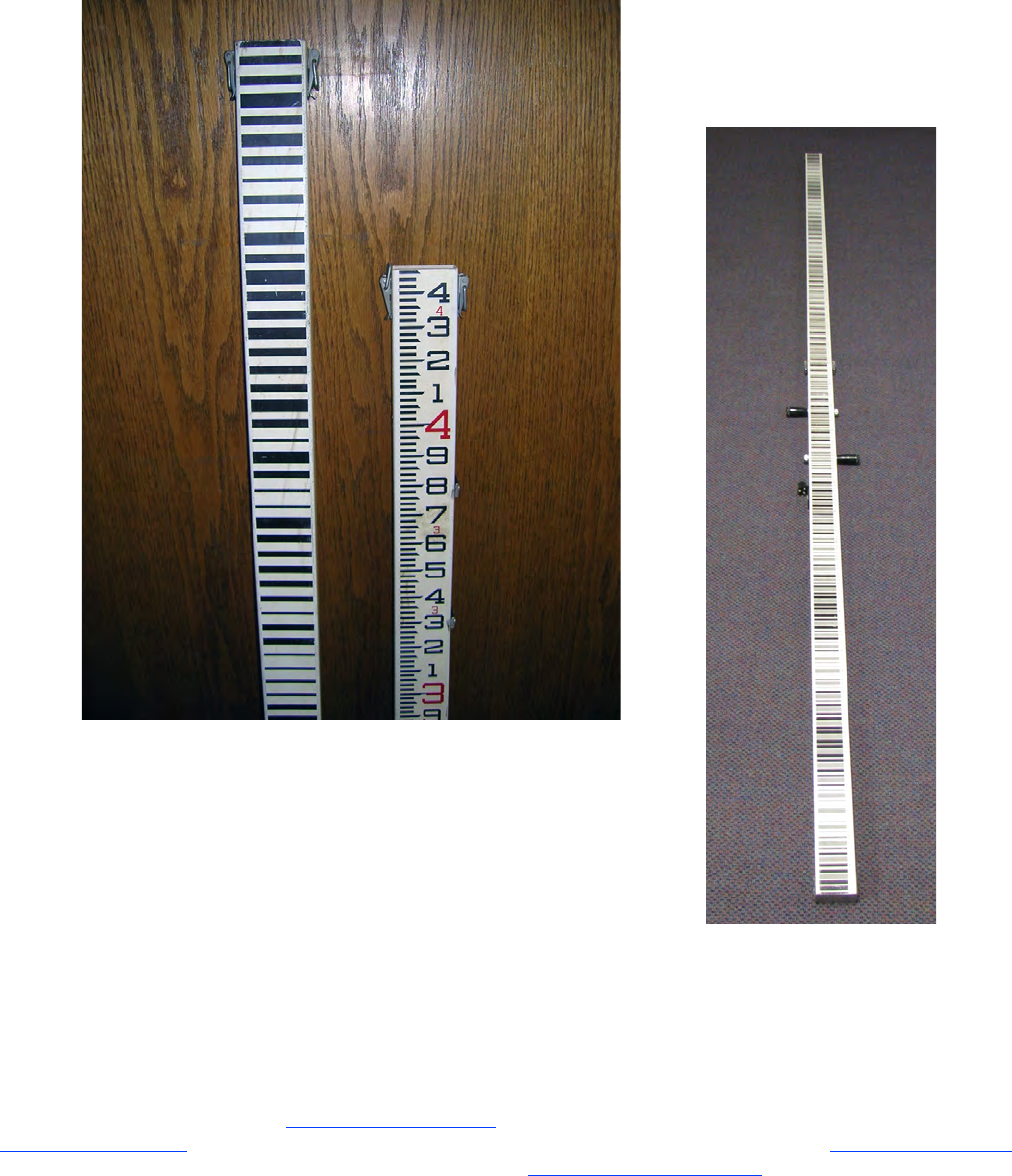

Electronic digital levels (g. 3) automatically read a

bar-code leveling rod (g. 4) held on an objective point.

When using an electronic digital level, the operator sights in

the bar-code leveling rod using the optical view nder and

then interrogates the instrument to make a measurement. The

instrument then shows the value on its digital display screen.

Many electronic digital levels are equipped with logging

and computational functions that can be used when running

levels. Electronic digital levels contain optical systems that

also allow the level to be used manually. Like optical levels,

distances to objective points and environmental conditions

can limit the utility of electronic digital levels. Electronic

digital levels provide some distinct advantages over optical

levels; for example, because the instrument automatically

reads the leveling rod, any subjectivity in manually estimating

the measurement to 0.001 ft is removed. Similarly, the

potential for misreading the leveling rod is eliminated when

using electronic digital levels. When using data-logging

features common to many electronic digital levels, errors

associated with manually transcribing measurements can

also be eliminated. A disadvantage of electronic digital levels

is that the electronic nature of these instruments introduces

the potential for system failures to occur while in the eld.

Fortunately, the optical capability serves as a backup to the

electronic system. It is common when running levels at gaging

stations to use a secondary device, such as a steel tape, to

take shots on objects located in places where a rod cannot

be placed. Further, FSs to some objects (such as wire-weight

gages) are made by sighting in the object at the cross hair of

the instrument. Digital systems, which require a bar-code rod,

cannot be used for such shots. For these reasons, both the

optical and the digital systems of electronic digital levels must

be maintained and tested frequently.

Figure 2. Optical levels.

4 Levels at Gaging Stations

Figure 3. Electronic digital levels.

Parallax

A sharply focused level is important for accurate readings

of the leveling rod. A properly focused instrument locates the

graduations of the leveling rod at the plane of the cross hairs.

Parallax is the relative movement of the image of the leveling

rod with respect to the cross hairs as the observer’s eye moves.

This is caused by the objective lens not being focused on the

leveling rod (Kennedy, 1990). To check for parallax, slightly

move your eye up and down while sighting in a leveling rod. If

the rod appears to move with respect to the cross hair, parallax

is present. Parallax usually can be eliminated by adjusting the

objective focus. Diligence in refocusing the instrument for all

readings and checking for parallax will eliminate erroneous

measurements associated with improper focus.

Checking the Engineer’s Level

An engineer’s level is set up to measure the vertical

distance from objective points to the level plane of the

instrument. When applying the techniques of differential

leveling, a properly leveled instrument is assumed to be on a

horizontal plane at the determined elevation of the instrument

or instrument height. Collimation error is a measurement of

the inclination of a level’s line of sight (Breed and others,

1970; McCormac, 1983; Kennedy, 1990), or the deviation

from the horizontal plane. Collimation error is reported as

a vertical deviation over a set distance, such as 0.xxx ft per

100 ft. If horizontal distances from the instrument to each

object that a FS or BS is taken on are known, collimation

corrections can be computed and applied. However, levels

at gaging stations do not require measurements of horizontal

distance, and therefore, the collimation error of the instrument

is preserved in all measurements and is not corrected for.

Differential Leveling and Leveling Equipment 5

A

B

IP021599_Figure 4. Rods

Figure 4. Bar-code leveling rods. A. separated multi-section rod

showing the self-reading rod scale on the second side.

Collimation error of an engineer’s level is determined by

running a xed-scale test, a two-peg test, or another accepted

collimation test. These tests check how true the instrument

is sighting on a horizontal plane. Given the precision with

which gaging-station levels are run (0.001 ft) and the criteria

that determine a valid level run at a gaging station (these are

outlined in detail in the section on “Assessing a Level Circuit

and Adjusted Elevation”), the tolerance for the collimation

error of an instrument cannot exceed the absolute value (| |)

of 0.003 ft/100 ft. Instruments possessing collimation errors

greater than |0.003| ft/100 ft should be adjusted by qualied

personnel or by a certied facility. Following any adjustments

made to an instrument, a collimation test must be performed

and documented to verify that the instrument was adjusted

correctly.

The criteria for an acceptable level run include a limit

on circuit-closure error and a maximum difference between

the rst and second elevations of any objective point in the

level circuit. Conditions exist that can cause an instrument

with a collimation error greater than |0.003| ft/100 ft to yield

results that meet the criteria for an acceptable level circuit and

yet still produce nal elevations that are incorrect because of

the collimation error (see section on “Collimation Error and

Balanced Sightline Distances”). In order to minimize errors

associated with instrument calibration, a collimation test

(xed-scale, peg, or other accepted test) must be performed

and documented at least once per week (National Oceanic

and Atmospheric Administration, 1981; Federal Geodetic

Control Committee, 1984) for each week that gaging-station

6 Levels at Gaging Stations

levels are run. There should not be more than 7 days between

a collimation test and a set of levels. If a level is found to

have a collimation error greater than |0.003| ft/100 ft, all

gaging- station levels run since the previous collimation

test must be discarded and re-run. For this reason, it is

recommended to run collimation tests more frequently. When

electronic digital levels are used, these tests should be done for

both the optical and digital systems.

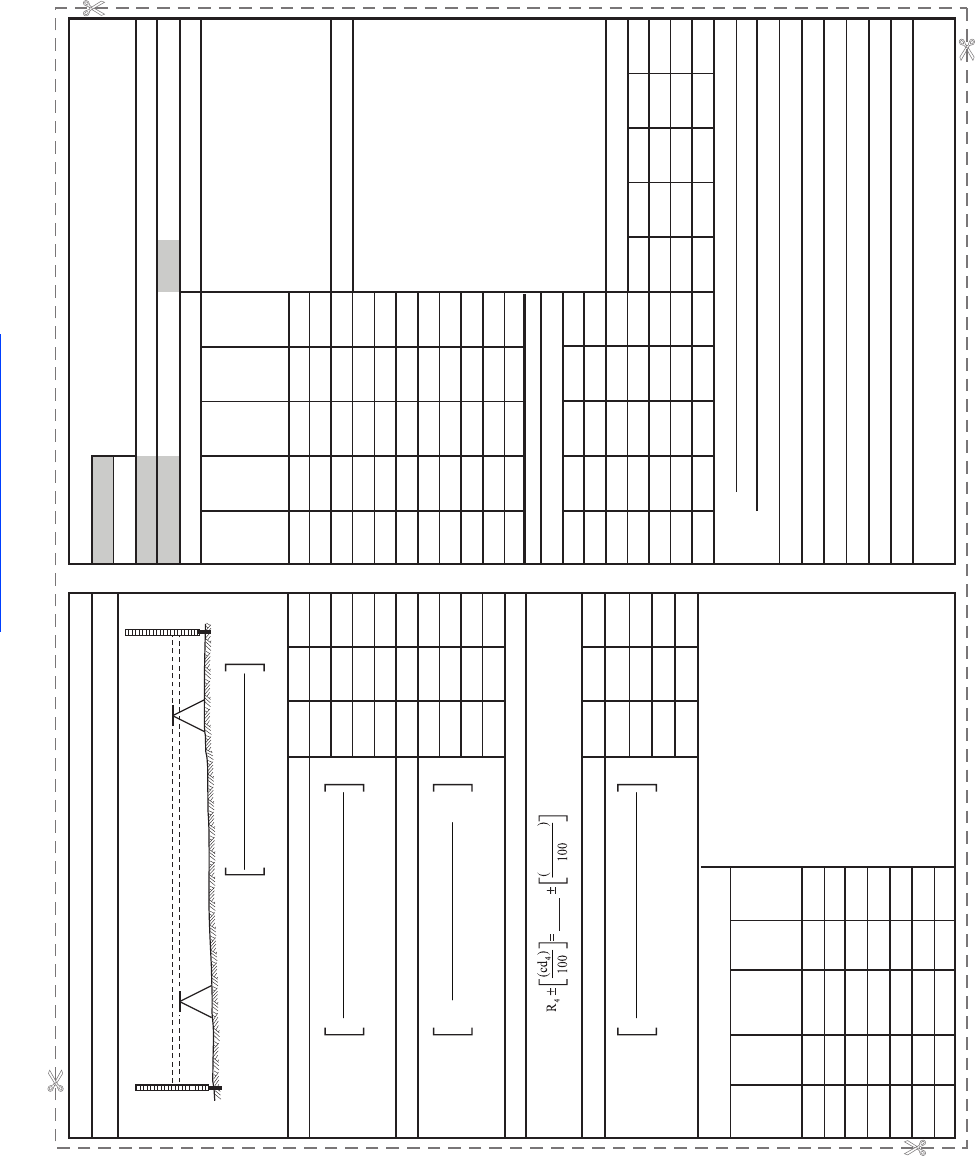

Fixed-Scale Test

A xed-scale test uses two mounted rod scales set to

the same datum and spaced about 120 ft apart to determine

the collimation error of an instrument (g. 5). A xed-scale

test can be set up outdoors between trees, deeply set posts,

or buildings at a reasonably level location, or can be set up

indoors; for example, between columns or doorframes in a

long corridor of a large building (Kennedy, 1990). To install

the scales, place the instrument equidistant from the mounting

locations. Install each scale such that the readings from the

level to each scale are equal. To test the collimation of the

level, set it up as close as possible to one scale. Read each

scale from this location, and measure the horizontal distances

to each scale. The length of d

2

should not exceed 110 ft to

avoid curvature and refraction effects. Horizontal distances

can be determined using the stadia hairs of the level, the

distance reported by an electronic digital level, or a measuring

tape. From these readings, the collimation error can be

computed using the equation (Kennedy, 1990):

1 2

2 1

1

2

( )

100* ,

( )

where

is the collimation error, in unit length

per 100 unit lengths,

is the reading obtained from the near

rod scale, in unit length,

is the reading obtained from the far

R R

c

d d

c

R

R

−

=

−

1

2

rod scale, in unit length,

is the distance to the near rod scale,

in unit length, and

is the distance to the far rod scale, in

unit length, which should be less

than 110 ft.

d

d

(1)

If the absolute value of the collimation error is greater than

0.003 ft/100 ft, the level must be adjusted. A diagram of a

xed-scale test showing the variables of equation 1 is shown

in gure 5. A xed-scale test form is provided in appendix A.

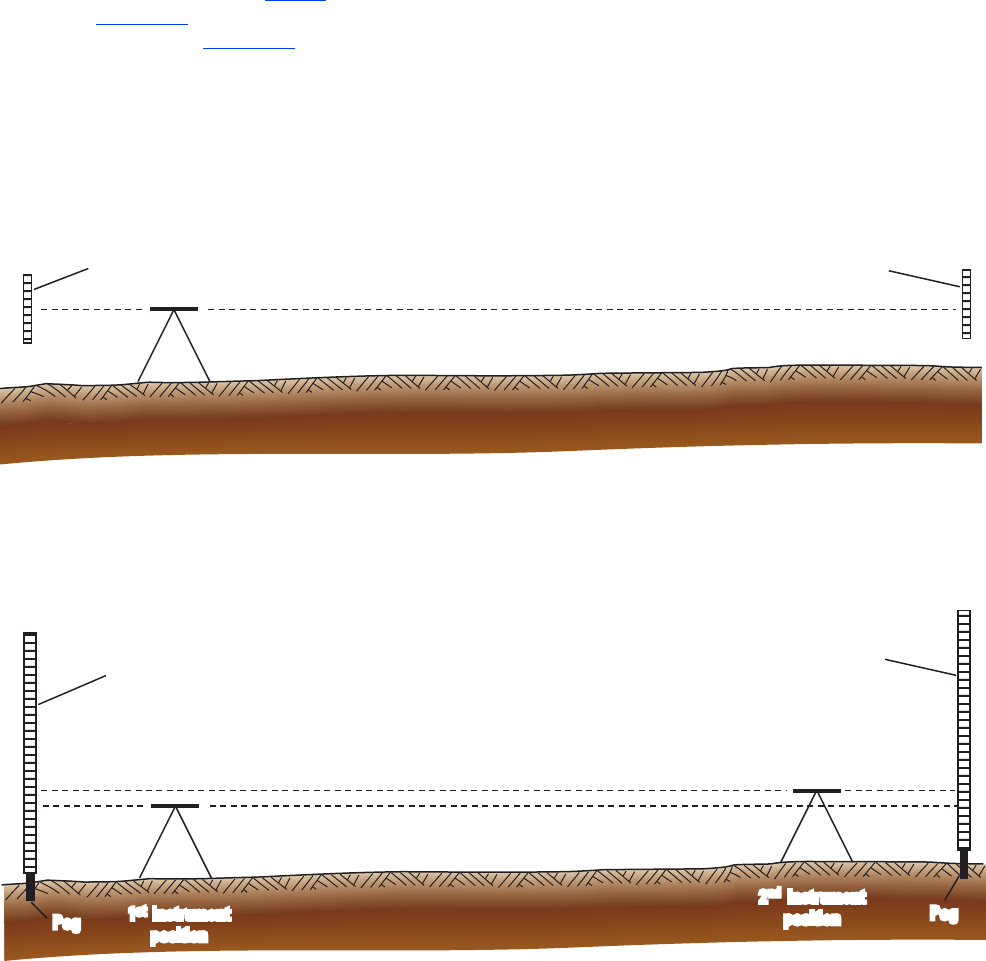

Peg Test

A peg test does not require scales to be mounted and

can be run with the instrument and rod in any reasonably

level location. Several versions of peg tests are used. The

one described here, commonly referred to as a two-peg test,

was adapted from the USGS Geography Discipline, formerly

known as the USGS Survey and National Mapping Division

(Kennedy, 1990). Two pegs or marks should be established

and spaced about 120 ft apart (g. 6). The instrument is set up

as close as possible to one of the pegs. Shots are taken to the

rod held on the near peg and the far peg. Distances from the

instrument to the pegs are measured, using the stadia hairs,

the digital system, or a measuring tape. The instrument is then

moved as near as possible to the other peg, and again shots

are taken to each and distances are measured. From these

measurements the collimation error can be computed using the

equation (Kennedy, 1990):

1 3 2 4

2 4 1 3

1

2

( ) ( )

100* ,

( ) ( )

where

is the collimation error, in unit length

per 100 unit lengths,

is the reading taken on the near peg

from the first instrument setup,

in unit length,

R R R R

c

d d d d

c

R

R

+ − +

=

+ − +

3

4

is the reading taken on the far peg

from the first instrument setup,

in unit length,

is the reading taken on the near peg

from the second instrument

setup, in unit length,

is the reading taken on th

R

R

1

2

e far peg

from the second instrument setup,

in unit length,

is the distance to the near peg

from the first instrument setup,

in unit length,

is the distance to the far peg from

the first instrument

d

d

3

4

setup, in unit

length,

is the distance to the near peg from

the second instrument setup, in

unit length, and

is the distance to the far peg from the

second instrument setup, in unit

length.

d

d

(2)

Differential Leveling and Leveling Equipment 7

The average of d

2

and d

4

should be less than 110 ft to avoid

curvature and refraction effects. If the absolute value of the

collimation error is greater than 0.003 ft/100 ft, the instrument

must be adjusted. A diagram of a peg test showing the

variables of equation 2 is shown in gure 6. A peg test form

is provided in appendix B and is also contained in the Gaging

Stations Level Notes form (appendix C).

Manufacturer-Recommended Collimation Test

Some manufacturers of level instruments provide

a recommended method for testing and adjusting for

collimation error. Some of the electronic digital levels

contain preprogrammed tests and adjustment routines

that provide for efcient and convenient collimation

checks. Some preprogrammed checks may require the

instrument to be located a specied distance from the rod.

If manufacturer- recommended methods meet the 0.001-ft

precision and the less than 0.010-ft accuracy requirements for

gaging-station levels and report collimation error as a vertical

deviation over a specied distance, they can be used as the

weekly collimation test. Weekly tests are required for both the

optical and digital systems of the electronic instruments.

Figure 5. Engineer’s level and rod scales set up for the fixed-scale test. R, the reading obtained from a rod scale; d, the distance

to a rod scale. Modified from Kennedy (1990).

R

1

R

2

d

1

d

2

IP021599_Figure 5. Schematic of fixed scale test.

Fixed scale

Fixed scale

Instrument

Figure 6. Engineer’s level and leveling rods set up for the two-peg test. R, the reading obtained from a leveling rod; d, the

distance to a peg. Modified from Kennedy (1990).

R

1

R

3

R

2

R

4

d

1

d

2

d

3

d

4

IP021599_Figure 6. Schematic of peg test.

1 Instrument

position

st

2 Instrument

position

nd

Leveling rod

Leveling rod

Peg

Peg

8 Levels at Gaging Stations

Collimation Error and Balanced Sightline

Distances

Collimation error is a measure of the inclination of a

level’s line of sight. Unless corrected using measurements of

horizontal distance, this systematic error is preserved in all

measurements made with the level. Balancing the sightline

distances to all objects to which shots are taken minimizes

the effects of collimation error on nal elevations. However,

balancing sightline distances in a gaging-station level circuit

is often not feasible. Under ideal conditions when sightline

distances are perfectly balanced, collimation error preserved

in FSs and BSs does not affect the nal computed elevations.

An example is an instrument that has a high collimation error

of 0.010 ft/100 ft and sightline distances that equal 100 ft

(table 1). Each BS and FS shows an error of 0.010 ft, because

the instrument has a collimation error of 0.010 ft/100 ft and

the distances are all 100 ft. Even though each shot contains

collimation error, because the horizontal distances are equal,

the error in each shot is equal. The collimation error indicates

that the line of sight of the level is angled downwards causing

readings of the leveling rod to be 0.010 ft low. Because the

errors are equal for each shot, the true differences in elevation

between the objective points can be accurately determined, and

therefore, the nal elevations of the objective points are the

true elevations and the circuit-closure error is 0.000 ft. If this

were a level circuit, ideally the level would not be used because

the absolute value of the collimation error is greater than

|0.003| ft; however, because the sightline distances are perfectly

balanced, the collimation error does not adversely affect

the nal elevations because the true differences in elevation

between the objective points are determined in this circuit.

Collimation error begins to have a profound effect

on nal elevations when sightline distances are extremely

unbalanced. However, the effect of collimation error can be

masked when the distances between the instrument and the

objective points remain the same for the second instrument

setup. Table 2 provides an example of how the effects of

collimation error can go unnoticed. This example uses the

same level circuit as the previous example, but sightline

distances range from 10 to 200 ft. In this circuit, the distance

to each of the objects remained the same for the second

instrument setup. Errors contained in each BS and FS ranged

from 0.001 to 0.020 ft. In a real gaging-station level circuit,

these errors would not be known because horizontal distances

are not measured. The two elevations acquired for each

objective point differ from the true elevations, yet the closure

error is 0.000 ft. In this example circuit, an instrument with

a large unknown collimation error was used, and unless a

comparison was made with the historical elevations, one

would assume that the level circuit met the criteria for a

valid level circuit of closure error and the difference between

adjusted rst and second objective point elevations (discussed

in detail below). This introduces the potential for gages to be

set or adjusted incorrectly during a level run.

The sightline distances should be inverted in order to

reveal collimation errors in a circuit consisting of unbalanced

sightline distances, which, as shown above, can produce

erroneous nal elevations. In the previous example with

unbalanced sightline distances, the second instrument setup

was located in the same position as the rst instrument setup.

The level circuit appeared to be valid, as evidenced by a

closure error of 0.000 ft and no differences between rst

and second elevations for each objective point, yet the nal

Object

Distance

from

instrument

to object

BS

error

1

BS HI

FS

error

1

FS Elevation

Closure

error

1st and 2nd

elevation

differences

True

elevations

Difference

from true

elevation

RM1 (origin) 100 0.010 5.260 105.260 0.010 NA

2

100.000 NA NA 100.000 NA

RM2 100 NA NA NA 0.010 7.121 98.139 NA NA 98.139 0

RM3 100 NA NA NA 0.010 2.042 103.218 NA NA 103.218 0

TP 100 NA NA NA 0.010 3.343 101.917 NA NA 101.917 0

Instrument moved and re-leveled

TP 100 0.010 4.343 106.260 0.010 NA 101.917 NA NA 101.917 0

RM3 100 NA NA NA 0.010 3.042 103.218 NA 0 103.218 0

RM2 100 NA NA NA 0.010 8.121 98.139 NA 0 98.139 0

RM1 100 NA NA NA 0.010 6.260 100.000 0.000 NA 100.000 0

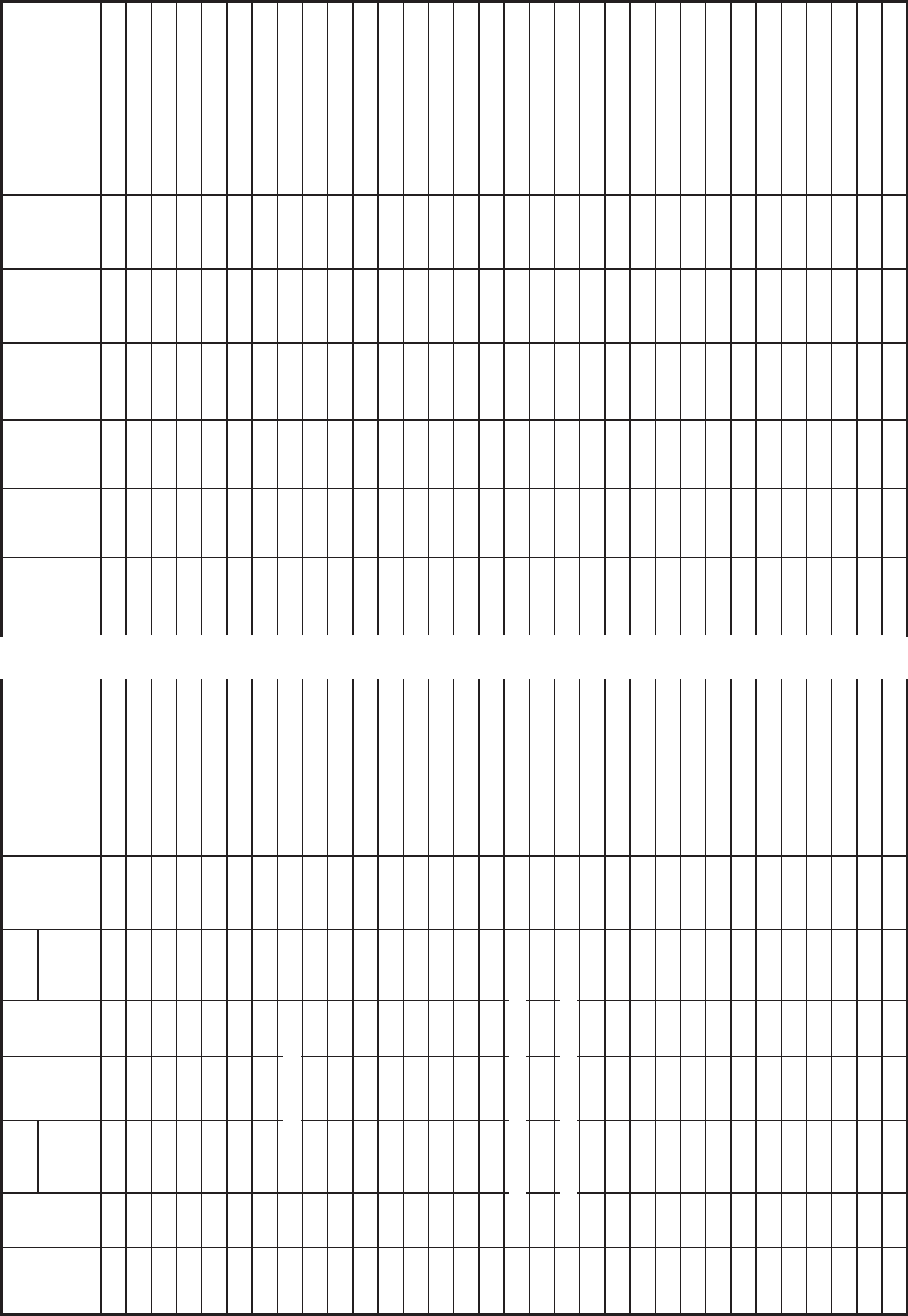

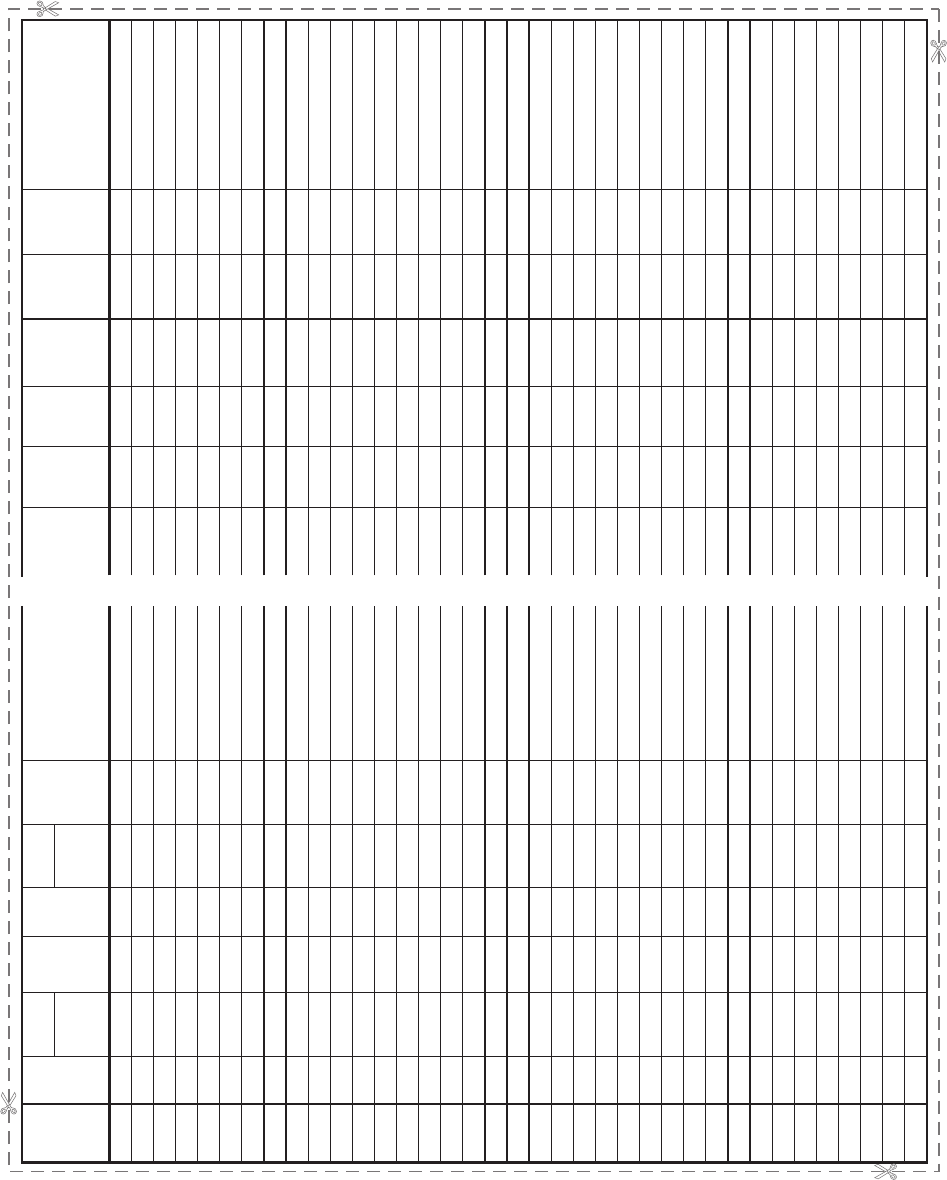

Table 1. Notes for gaging station levels run when all sightline distances are equal and the instrument used has a collimation error of

0.01 foot per 100 feet.

[All values are given in feet. Elevations are referenced to an arbitrary gage datum. BS, backsight; HI, height of instrument; FS, foresight; RM, reference mark;

TP, turning point; NA, not applicable]

1

Computed from the collimation error and the distance from the instrument to the object.

2

Given elevation in the level circuit.

Differential Leveling and Leveling Equipment 9

Object

Distance

from

instrument

to object

BS

error

1

BS HI

FS

error

1

FS Elevation

Closure

error

1st and 2nd

elevation

differences

True

elevation

Difference

from true

elevation

RM1 (origin) 10 0.001 5.251 105.251 0.001 NA

2

100.000 NA NA 100.000 NA

RM2 100 NA NA NA 0.010 7.121 98.130 NA NA 98.139 –0.009

RM3 150 NA NA NA 0.015 2.047 103.204 NA NA 103.218 –0.014

TP 200 NA NA NA 0.020 3.353 101.898 NA NA 101.917 –0.019

Instrument moved and re-leveled

TP 200 0.020 4.353 106.251 0.020 NA 101.898 NA NA 101.917 –0.019

RM3 150 NA NA NA 0.015 3.047 103.204 NA 0.000 103.218 –0.014

RM2 100 NA NA NA 0.010 8.121 98.130 NA 0.000 98.139 –0.009

RM1 10 NA NA NA 0.001 6.251 100.000 0.000 NA 100.000 0.000

Table 2. Notes for gaging station levels run when sightline distances between the instrument and objects vary in the same order for

two setups and the instrument used has a collimation error of 0.01 foot per 100 feet.

[All values are given in feet. Elevations are referenced to an arbitrary gage datum. Distances from the instrument to each object remained the same after the

instrument was moved. BS, backsight; HI, height of instrument; FS, foresight; RM, reference mark; TP, turning point; NA, not applicable]

1

Computed from the collimation error and the distance from the instrument to the object.

2

Given elevation in the level circuit.

elevations were incorrect, because the FS errors caused by

the collimation error of the instrument were equal for the two

shots taken to each objective point.

Table 3 shows an example of the same level circuit

run with an instrument with the same collimation error of

0.010 ft/100 ft, but with the sightline-distances inverted so that

the object farthest from the initial instrument setup is closest

to the instrument for the second setup. The range of error

contained in the FSs and BSs associated with the collimation

error of the instrument is similar to those in the previous

example because the same distances were used. Again, these

errors would not be known because the horizontal distances

are not measured when levels are run at gaging stations. By

inverting the sightline distances a signicant closure error

is revealed. If this example were an actual level circuit and

the instrument had a large (unknown) collimation error,

the sightline distances were unbalanced, but the sightline

distances were inverted for the second instrument setup, the

closure error criterion for a valid level circuit would have

indicated a problem with the circuit. By inverting the sightline

distances in a circuit that has unbalanced sightline distances,

unknown collimation errors of an instrument can be reected

in the closure error. If the location of objective points and

the locations for setting up the instrument cause unbalanced

sightline distances to be unavoidable, it is recommended that

these distances be inverted so that the object that was farthest

from the rst instrument setup becomes closest to the second

instrument setup. The technique of inverting the sightline

distances is designed to expose any unknown instrument error

in the circuit closure error, thus alerting the user of possible

systematic instrument error.

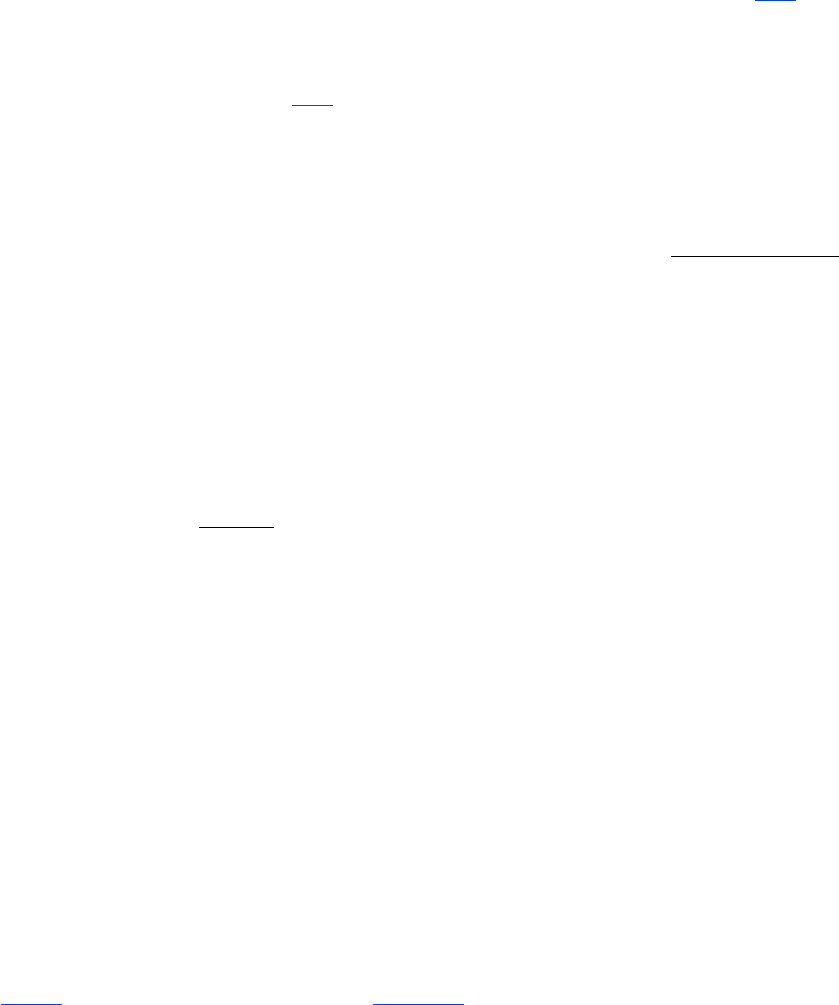

Leveling Rods

Many kinds of leveling rods are available for use in

running levels at gaging stations. Rods come in different

lengths, many are expandable, and they are made of different

materials. Many rods, such as the “Philadelphia” or “Chicago”

style rods, are made of a structural material, often wood or

berglass, and a rod-scale material, such as Invar or steel.

Invar is a nickel steel alloy, commonly used for precise

measuring equipment and has a very low coefcient of thermal

expansion (CTE). Self- reading rods with numeric scales

(g. 7) are used with optical engineer’s levels, while electronic

digital levels use leveling rods with bar-code scales (g. 4).

The scales of self-reading rods are typically divided into feet

and tenths and hundredths of feet by means of alternating

black and white spaces (McCormac, 1983) (g. 8). Bar-code

leveling rods often have a self-reading scale on the second

side of the rod to use with the optical system of the instrument

(g. 4A). For gaging-station levels, self-reading rods must

be graduated to 0.01 ft and readings are visually interpolated

in order to meet the measurement-precision requirement of

0.001 ft. Regardless of the type of engineer’s level, when

running levels at gaging stations, it is good practice to not

extend a rod more than about 16 ft because of the difculty

in holding a tall rod steady and level on an objective point. A

leveling rod should always be used in conjunction with a rod

level.

10 Levels at Gaging Stations

Inspection of Leveling rod

Leveling rods should be examined regularly to ensure

that their scales are set correctly and that their structure,

specically the bottom surface, is free of damage or debris. If

a leveling rod is found to be damaged it should be removed

from service. Thermal expansion or contraction of the material

of the rod scale should be considered when the rod is used

for gaging-station levels. The most common materials for

leveling-rod scales include Invar, berglass, steel, and wood.

Most rod scales are calibrated at the standard temperature of

68°F. The entire scale length for a self-reading rod should

be veried with an independent measuring tape from the

bottom of the rod. Similar independent verication checks of

all other measuring devices used when running levels should

also be done. All verications should be made indoors at the

standard temperature of 68°F. Rods should be checked with

a measuring tape at each foot marking along the length of the

scale and at both sides of any joints between scale sections.

If all graduations are accurate to within |0.002| ft, the rod is

satisfactory (Kennedy, 1990). If a rod scale is found to be

outside of the |0.002|-ft tolerance, adjust the scale if possible

or remove the leveling rod from service. At temperatures

greater than the calibration or standard temperature, the rod

scale will expand causing measurements to be lower than

they actually are, and at temperatures less than the calibration

temperature, contraction of the rod scale will have the opposite

effect. To minimize both errors in shots taken to leveling

rods, and the need to apply corrections to measurements due

to thermal expansion or contraction, it is recommended that

leveling rods (including all devices used as rods during level

Object

Distance

from

instrument

to object

BS

error

1

BS HI

FS

error

1

FS Elevation

Closure

error

True

elevations

Difference

from true

elevation

RM1 (origin) 200 0.020 5.270 105.270 0.020 NA

2

100.000 NA 100.000 NA

RM2 150 NA NA NA 0.015 7.126 98.144 NA 98.139 0.005

RM3 100 NA NA NA 0.010 2.042 103.228 NA 103.218 0.010

TP 10 NA NA NA 0.001 3.334 101.936 NA 101.917 0.019

Instrument moved and re-leveled

TP 200 0.020 4.353 106.289 0.020 NA 101.936 NA 101.917 0.019

RM3 150 NA NA NA 0.015 3.047 103.242 NA 103.218 0.024

RM2 100 NA NA NA 0.010 8.121 98.168 NA 98.139 0.029

RM1 10 NA NA NA 0.001 6.251 100.038 -0.038 100.000 0.038

Table 3. Notes for gaging station levels run when sightline distances between the instrument and objects vary inversely for two setups

and the instrument used has a collimation error of 0.01 foot per 100 feet.

[All values are given in feet. Elevations are referenced to an arbitrary gage datum. BS, backsight; HI, height of instrument; FS, foresight; RM, reference mark;

TP, turning point; NA, not applicable]

1

Computed from the collimation error and the distance from the instrument to the object.

2

Given elevation in the level circuit.

Figure 7. Self-reading leveling rods.

Differential Leveling and Leveling Equipment 11

runs) be used at temperatures near the calibration temperature

of the rod scale whenever possible. Determining the need

for and computing temperature corrections is discussed

in the section on “Correcting for Rod Scale Expansion or

Contraction Due to Temperature Variations.”

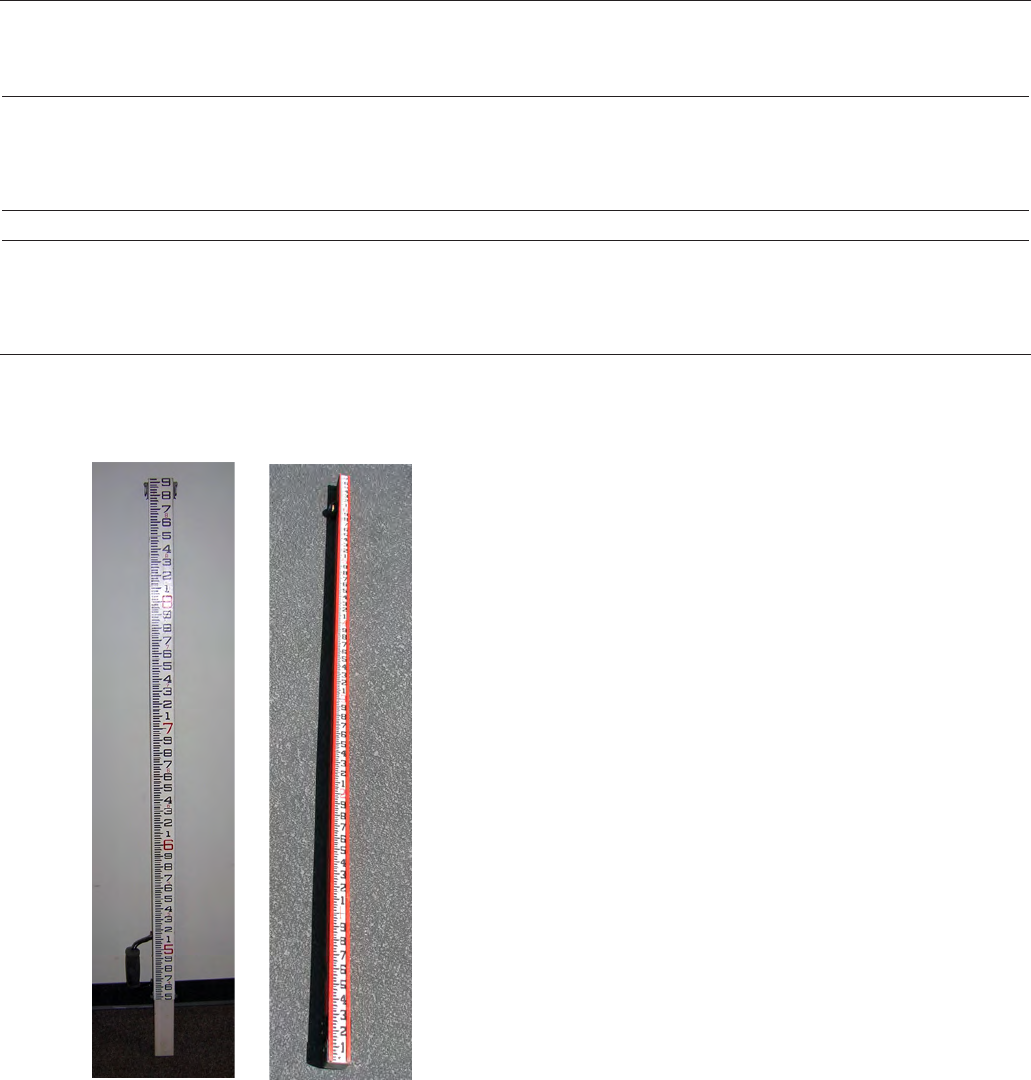

Proper Care and Use of a Rod Level

It is important that the leveling rod be held vertical

when levels are run at gaging stations. To ensure that the

leveling rod is vertical, a rod level should always be used.

Rod levels are either stand alone (g. 9A) and are used with

multiple leveling rods, or permanently attached and dedicated

to a single leveling rod (g. 9B). The stand-alone rod levels

consist of a bull’s eye bubble level mounted on a 90-degree

or square channel material. The 90-degree channel allows the

rod level to be held along the vertical axis of either a square or

round leveling rod. Rod levels should be checked for plumb

regularly and adjusted if necessary. To test the rod level, any

corner such as a wall corner that has been veried to be level

Figure 8. Scale of a self-reading Philadelphia rod.

This reading is 2.140 ft

Feet are marked by

red numbers.

Tenths of feet are

represented by

black numbers.

The x.x00 and x.x50

marks on strips are

pointed.

This reading is 2.050 ft

Small red numbers

indicate the

associated foot

sections

This reading is 2.127 ft

Foot marks are represented

with long strips

Hundredths of feet are represented

by the top and bottom of black

strips. The top of strips represent

even numbers and the bottom of

strips represent odd numbers.

IP021599_Figure 8. Reading the rod.

using a carpenter’s level can be used. Most rod levels have

screws that are used to adjust how the bubble level is seated

in its mount. When checking for plumb, the bubble should be

examined for expansion. If the bubble has expanded beyond

the circular level indicator line, the rod level should be

discarded.

Correcting for Rod Scale Expansion or

Contraction Due to Temperature Variations

At constant temperatures, measurements can be precisely

corrected for expansion and contraction of the rod-scale

material due to temperature variation. All materials have

a determined coefcient of thermal expansion (CTE), and

the CTE for the rod scale should be readily available from

the manufacturer of the rod. Material compositions of rod

scales vary, particularly for berglass rods; therefore, it is

recommended that the rod scale CTE be obtained directly

from the manufacturer. For reference, CTE ranges for some

common leveling rod-scale materials are provided in table 4.

12 Levels at Gaging Stations

The rod-scale material-specic CTE, the standard temperature,

and the rod-scale temperature at the time the leveling rod is

used for a measurement are used in the following equation to

determine the correction for expansion or contraction due to

temperature variation:

CTE * ( ),

w

here

is the correction for expansion or

contraction due to temperature

variation,in unit length,

CTE is the rod scale material specific

coefficient of thermal expansion,

in 1/ degrees Fah

t o

t

C L T T

C

= −

− −

renheit or

1/ degrees Celsius (examples

contained in table 4),

is the length of the measurement,

in unit length,

is the rod scale temperature at the

time of the measurement, in

degrees Fahrenheit or de

L

T −

grees

Celsius, and

is the standard temperature, in

degrees Fahrenheit (usually 68 F)

or degrees Celsius (usually 20 C).

o

T

°

°

(3)

The rod-scale temperature, T, can be measured directly by an

infrared thermistor, or if the rod is not in the direct sun, air

temperature can be used as a surrogate for the rod temperature.

To determine whether corrections are needed for a given level

circuit, rst compute or estimate the maximum elevation

difference between the origin reference mark and any point in

the level circuit. This is the difference between the elevation

of the origin and either the highest or the lowest point that a

FS will be taken on. Substitute this difference for L in equation

3 and compute C

t

. If the absolute value of C

t

is greater than

0.003, all FSs and BSs of the circuit should be corrected for

temperature-related expansion or contraction. Individual FSs

and BSs taken during a level run can be corrected by adding

the rod reading to the computed expansion or contraction

correction value by using the equation

corrected read read

corrected

read

(CTE* ( )),

where

is the sight (backsight or foresight)

corrected for expansion or contraction

due to temperature variation, in unit

length,

is the sight (backsight

o

S S S T T

S

S

= + −

or foresight)

obtained from the leveling rod, in

unit length,

CTE is the rod-scale material-specific

coefficient of thermal expansion, in

1/degrees Fahrenheit or 1/degrees

Celsius (examples contained in table 4),

is the rod-scale temperature at the time

of the measurement, in degrees

Fahrenheit or degrees Celsius, and

is the standard temperature, in degrees

Fahrenheit (usually 68°F) or degrees

Cel

o

T

T

sius (usually 20°C).

(4)

A

B

Figure 9. Stand-alone A. and permanently attached B. rod levels.

Establishment of Gage Datum 13

Rod-scale

material

Approximate coefficient of thermal expansion

in length/length/degree

Fahrenheit (1/°F)

in length/length/degree Celsius

(1/°C)

Invar

1

0.8 × 10

–6

1.4 × 10

–6

Wood

1

2.1 × 10

–6

to 2.8 × 10

–6

3.8 × 10

–6

to 5 × 10

–6

Steel tape

2

6.45 × 10

–6

12 × 10

–6

Fiberglass

1

17 ×10

–6

to 22 × 10

–6

30.6 ×10

–6

to 39.6 × 10

–6

Table 4. Approximate coefficients of thermal expansion for

common leveling rod-scale materials.

1

From http://www.engineeringtoolbox.com/linear-expansion-

coefcients-d_95.html.

2

From Breed, Hosmer, and Bone (1970).

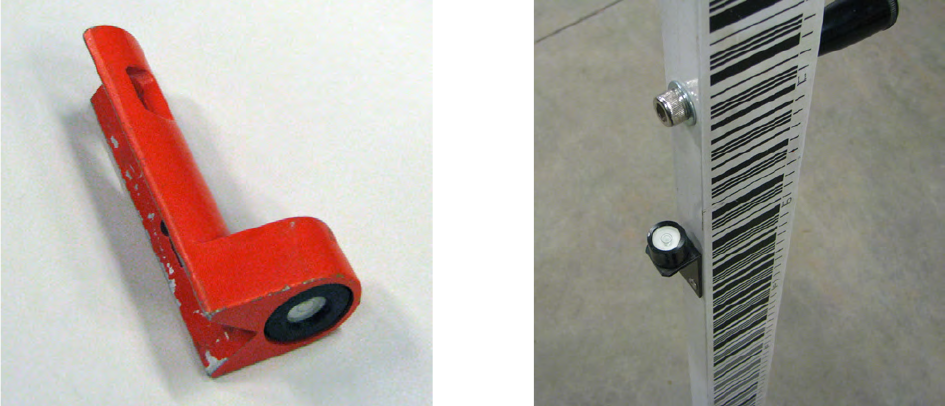

Considerations for Secondary Devices Used for

Vertical Measurements

When running levels at gaging stations, a secondary

measuring device other than a leveling rod might be required

to take FSs on gages or to carry elevations over a large vertical

distance. The CTE for the materials that compose secondary

devices used in a level circuit should be obtained and used to

correct FSs and BSs when appropriate. Any secondary devices

used must meet the precision and accuracy requirements of

gaging-station levels. When using a measuring tape to carry

elevations between a bridge deck and a low water bank,

the tape should be weighted so that the tape is not stretched

and the tension applied by the weight should ensure that the

tape is suspended vertically. Figure 10 is a photograph of

a steel tape with a 1-pound weight that is commonly used

for measuring water levels in wells. This same equipment

can be used for tape-down measurements or for carrying

elevations over a large vertical distance. The practical limit of

measurement precision for this tape-down method is ±0.01 ft

(U.S. Geological Survey, 1980). If used when running levels

at gaging stations to carry elevations between a bridge deck

and a low water bank, the FSs or BSs should be estimated to

0.001 ft.

Wind can have a profound effect on suspended measuring

devices, particularly those suspended from a bridge. Wind

will cause a suspended tape to bend and articially increase

the vertical distance the tape is spanning. Wind effects cannot

be accounted for, so vertical measurements using a suspended

measuring tape affected by wind should be avoided.

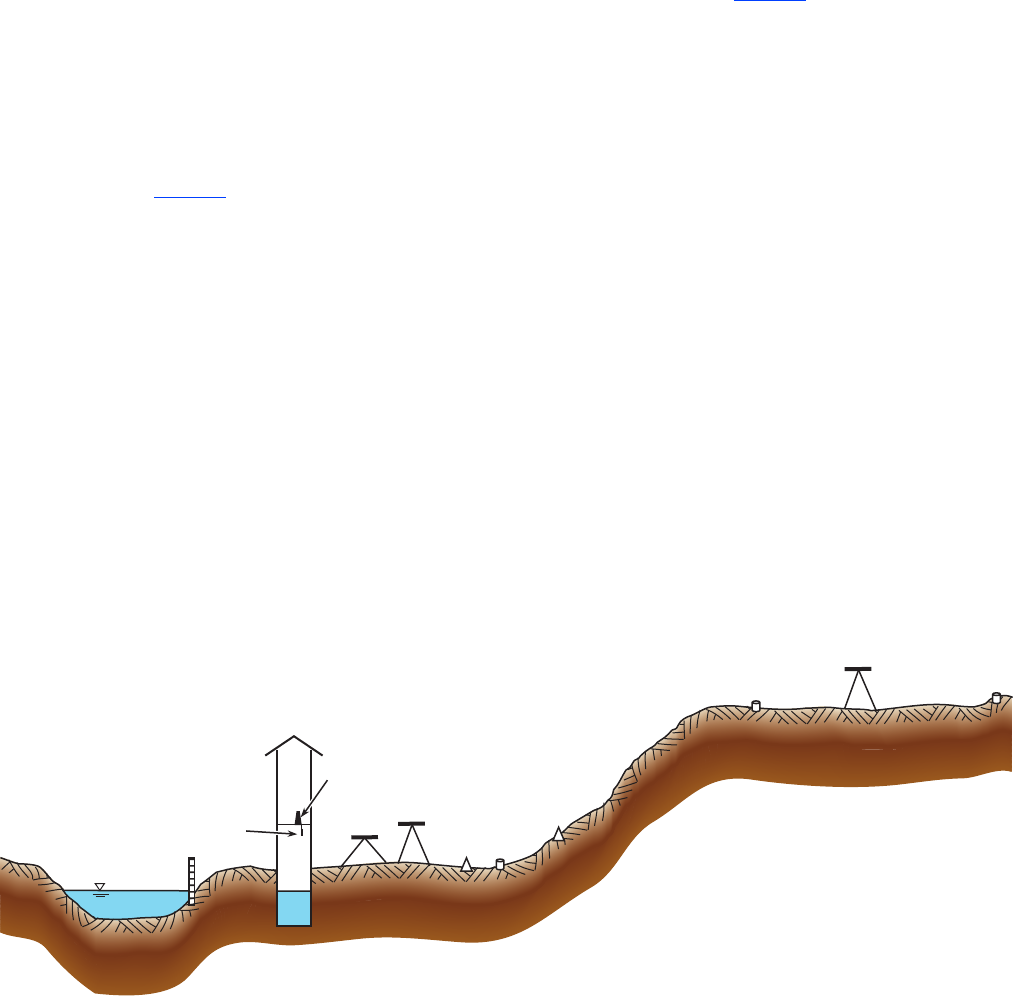

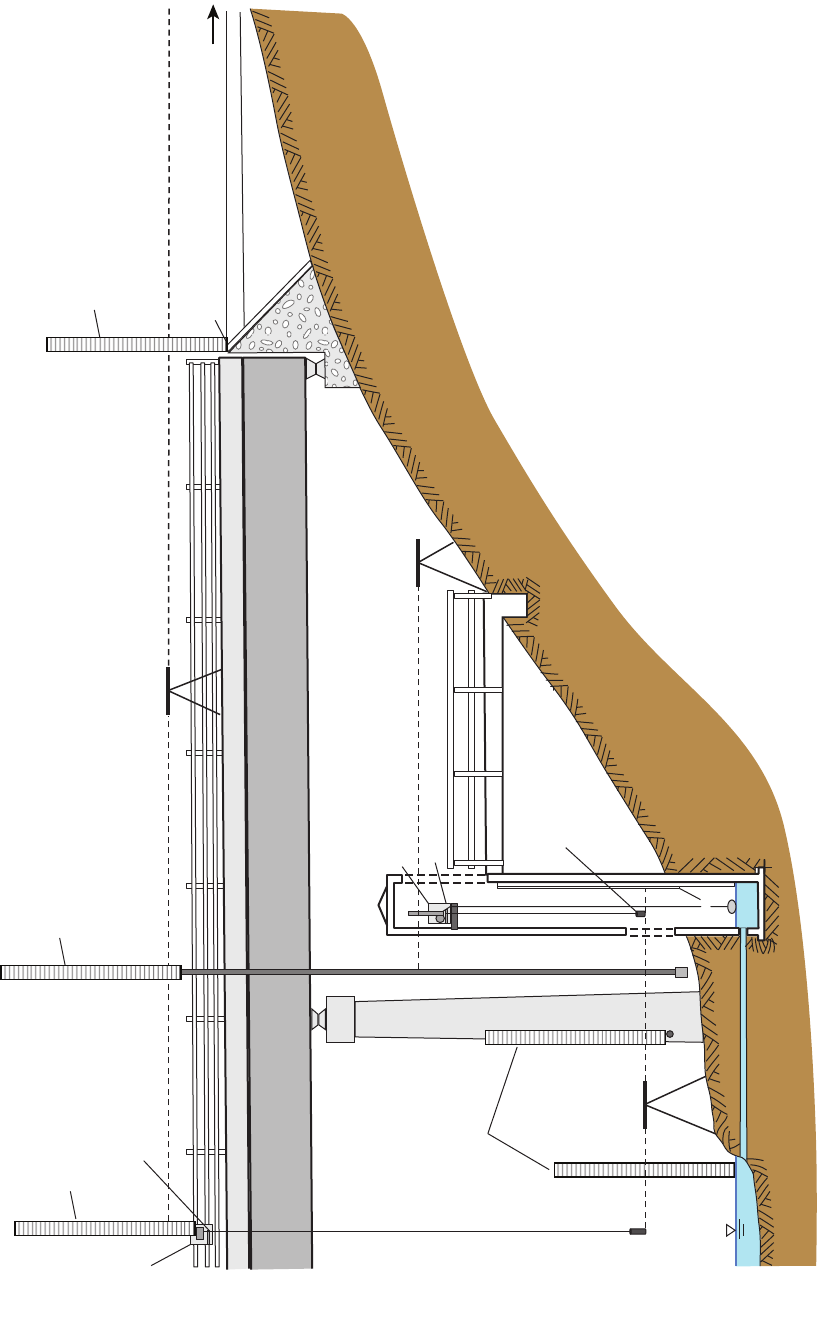

Establishment of Gage Datum

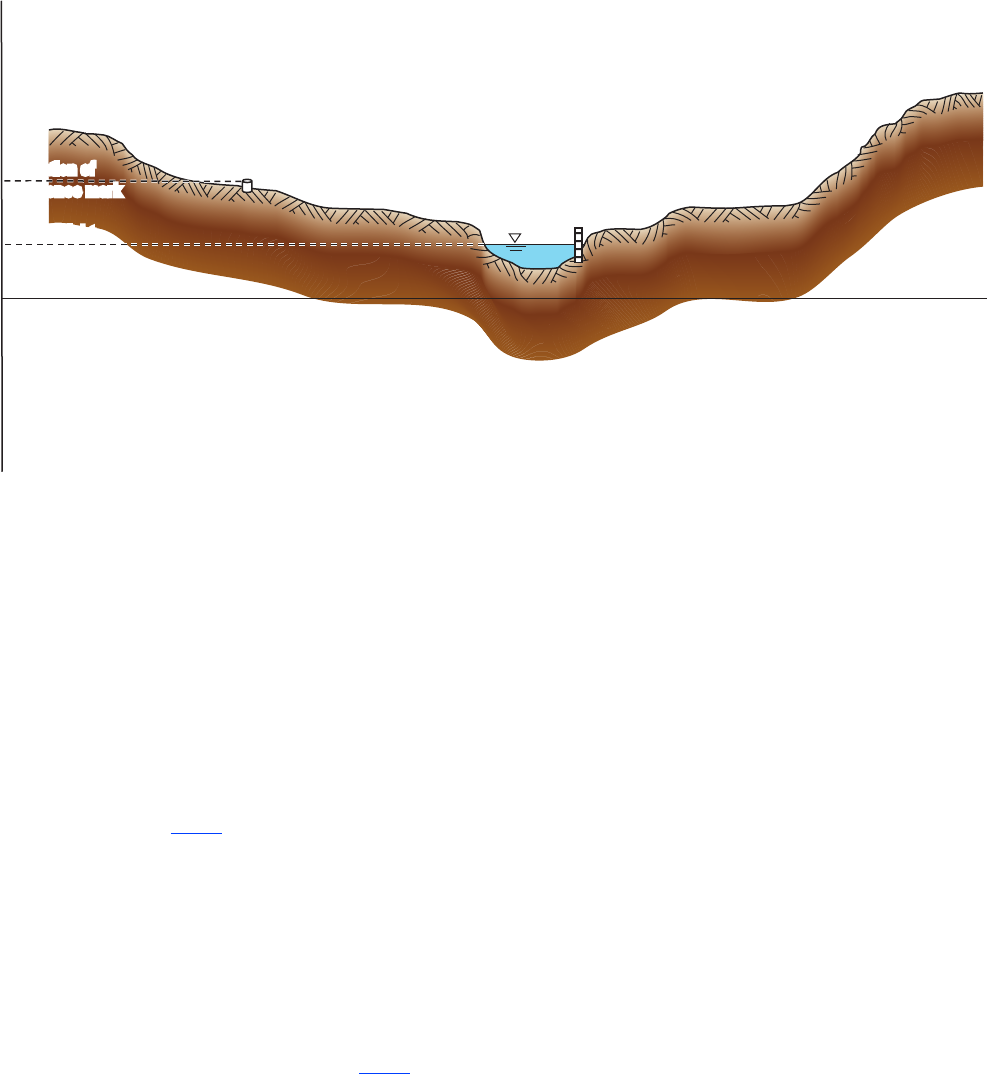

The gage datum is the reference surface at a gaging

station to which all gages are set (Corbett and others, 1943)

(g. 11). The reference surface is represented by the 0.000-ft

mark on the gages and should be located well below the

streambed, below any likely gage height of zero ow (GZF).

The gage datum is usually an arbitrary reference but it can

be tied to an established datum, such as the North American

Vertical Datum of 1988 (NAVD 88), through the use of

established benchmarks. When a gaging station is being

established where no station has existed previously, the gage

datum should be set low enough to ensure that the lowest

gage height ever likely to be recorded while the stream is

owing is at least 1 ft (Kennedy, 1990). When establishing

the gage datum, the current water depth over the hydraulic

control of the gage pool should be known and the potential

maximum streambed scour should be considered. Experience

with stream channels of similar materials, geometry, and

basin characteristics may provide some indication of the

potential magnitude of streambed scour. Because negative

gage heights are undesirable, the gage datum reference surface

that is selected should be well below the estimated maximum

scour depth to avoid negative gage heights over the life of the

station.

Figure 10. Steel tape with 1 pound of tension.

IP021599_Figure 10. Steel weight tape

14 Levels at Gaging Stations

Gage datum, 0.000 feet

Gage height

Elevation of

reference mark

ELEVATION IN GAGE DATUM

IP021599_Figure 11. Gage datum

Staff

gage

Water

surface

Reference mark

Figure 11. Gage datum at a station.

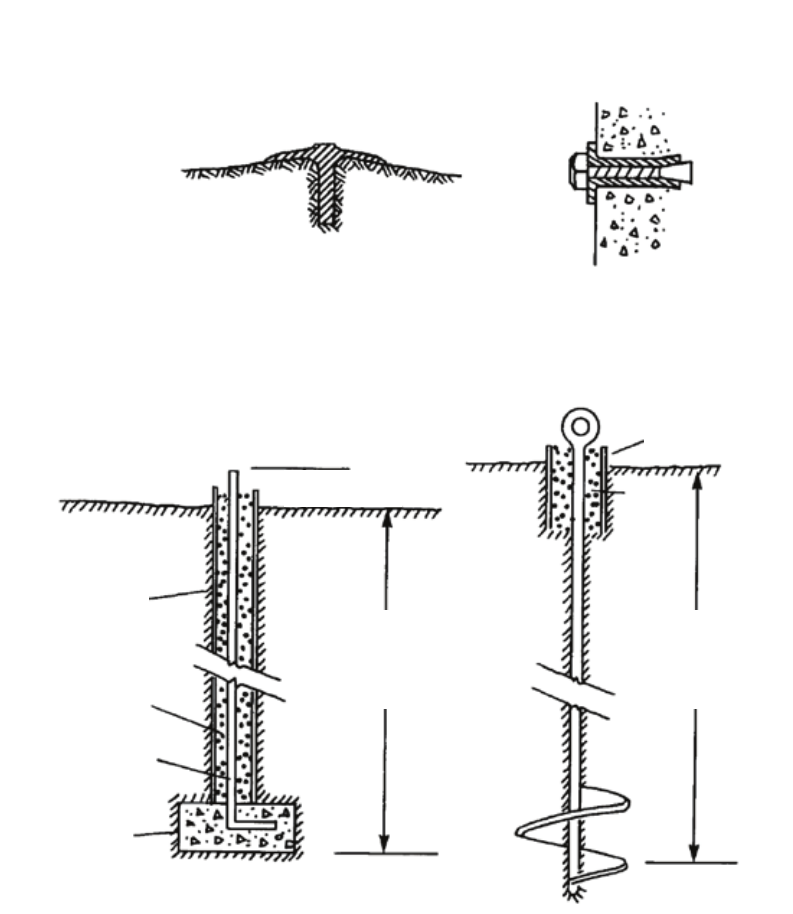

Installation of Reference Marks

Reference marks are installed and elevations are

determined in the gage datum when gaging stations are

established. Stable and permanent reference marks facilitate

maintaining that the gages at a station are set to the gage

datum over the life of the station. Typical reference marks

include gaging-station tablets cemented and drilled into rock

outcrops, bolts drilled into masonry walls, steel rods driven

and cemented into stable ground, and other earth anchors

located below frost lines (g. 12). Reference marks provide

a means for recovering the gage datum if the gaging station

is destroyed or is removed and reactivated sometime later.

The most stable locations for reference marks are often rock

outcrops and substantial masonry structures. Bridges often

provide a stable environment for reference marks; however,

bridges that sway or have a high trafc volume may not be

desirable because precise measurements are difcult to make

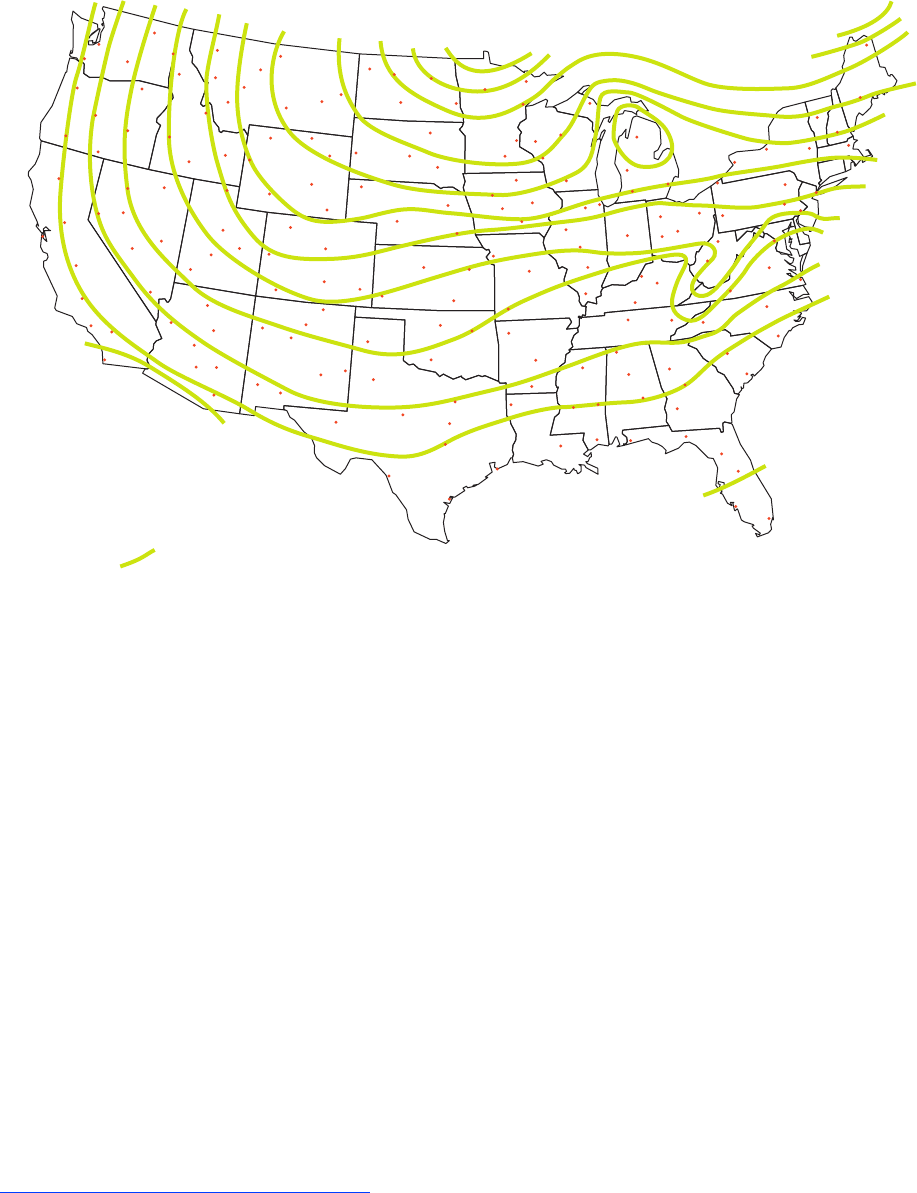

with a level and rod. In the absence of rock outcrops and

stable masonry structures, reference marks can be anchored at

depths below the local frost depth in stable soils (g. 13). The

methods used by the U.S. Department of Commerce, National

Oceanic and Atmospheric Administration, and National Ocean

Survey for establishing geodetic benchmarks (Floyd, 1978)

can provide guidance for installing reference marks. Clay soils

that expand and contract during seasonal variations in soil

moisture should be avoided (Kennedy, 1990).

Gaging stations should have a minimum of three

independent reference marks; more than three are

recommended whenever possible in case one (or more)

proves to be unstable or is destroyed. These marks should be

located independently of one another. For example, if one or

more reference marks are installed on a bridge structure, at

least two others should be installed somewhere away from

(and independent of) the bridge. Furthermore, reference

marks should be located independently of any gage, gage

infrastructure, or instream control structure, because reference

marks are used to track vertical changes over time to the gages

and to the other marks. If reference marks and gages are not

independent of one another, determining vertical differences

becomes difcult.

When locating reference marks, other considerations

should be made. Access to reference marks during ood

conditions is important to verify that the recorder is

accurately set to the gage datum in case the reference gage

is inaccessible. Ideally, at least one reference mark should

be located outside of the oodplain. When determining

the locations of reference marks, running levels should be

considered and, if possible, marks should be located so that

sightline distances are balanced and levels can be run in an

efcient manner. The potential for damage or destruction

of reference marks related to construction, specically road

construction or future land development, should be considered.

Finally, reference marks should be easily found from

descriptive statements in the station description document. As

discussed later, site sketches showing the location of reference

marks should be prepared. If vegetation is likely to obscure

marks over time, exact measurements from local objects

should be provided and a witness post should be installed.

Establishment of Gage Datum 15

Figure 12. Typical reference marks.

IP021599_Figure 12. Setting marks

Modified from Kennedy (1990).

Gaging-station tablet

cemented in hole drilled

in rock outcrop

3

/

8

-inch brass bolt and washer

in masonry wall

3

/

8

-in. reinforcing

steel

Steel rod in

concrete base

Earth anchor

4-inch PVC pipe

4-inch PVC pipe

lining

Concrete

base

3

-

4 inches

Below frost

line or at

a minimum

of 3 feet deep

Below frost

line or at

a minimum

of 3 feet deep

gravel

Clean gravel

16 Levels at Gaging Stations

Referencing a Gage Datum to an Established

Datum

It is desirable to reference an arbitrary gage datum to

a commonly used established datum, such as NAVD 88, at

all gaging stations. This is especially important at stations

used by the National Weather Service for ood forecasting

or at locations where ood proles are likely to be needed

(Kennedy, 1990). Generally, two methods are used to tie a

gage datum to an established datum - running a traditional

survey line and using a survey grade Global Positioning

System (GPS).

The rst method is to run a traditional survey line

consisting of a closed level circuit or a series of closed

level circuits from an established survey control point to

the origin or base reference mark of a gaging station. The

National Geodetic Survey (NGS) maintains a database

of established and maintained survey control points or

benchmarks throughout the United States that are available

at http://www.ngs.noaa.gov/cgi-bin/datasheet.prl. This

database can be used to nd the location of the nearest

control point and its elevation in NAVD 88. The distance

between the gaging station and an established survey control

point may be considerable and therefore the survey line

will consist of a number of different instrument setups and

turning points. Techniques for running survey lines from

established benchmarks outlined by the National Oceanic and

Atmospheric Administration (Schomaker and Berry, 1981)

should be used to tie gage datums to established datums.

The second method is to use a survey-grade GPS to

determine the elevation of a gaging station reference mark

above an established datum. Usually, the GPS is set up

over the reference mark of interest and allowed to collect

positional data over a set time interval. The uncertainty of

the positional data decreases with increased occupation time

over the reference mark. GPS technology and therefore the

recommended methods for collecting positional data using

a GPS, is continually changing. Follow currently accepted

agency guidelines and methods for determining elevations

with a survey-grade GPS.

After determining the elevation of a gaging station

reference mark above an established datum, the gage datum

can then be referenced, or tied, to the already established

datum. The gage datum is the 0.000 ft reference surface at

a gaging station. To determine the elevation of this surface

above the desired established datum, subtract the elevation of

the reference mark above the gage datum from the elevation

for the same reference mark above the established datum. All

other reference marks, reference points, and gages can then be

assigned elevations above the established datum by adding the

elevation of the gage datum above the established datum to

their elevation above the gage datum.

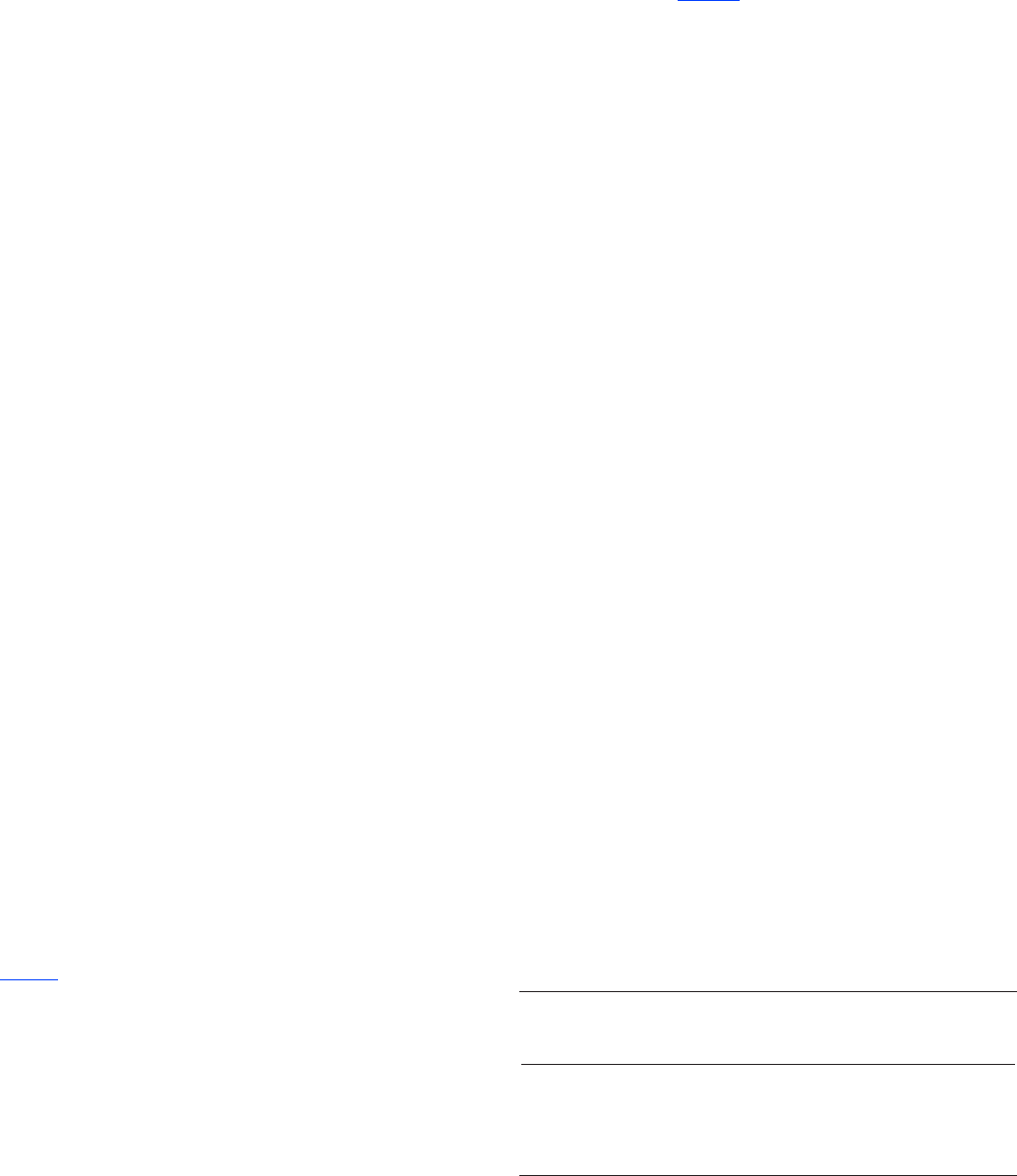

Figure 13. Extreme depth of frost map.

0.49

0.82

1.64

2.46

3.28

4.10

4.92

5.74

5.74

4.92

4.10

3.28

3.28

2.46

1.64

0.82

0.49

0

0

0

0

4.10

7.38

7.38

7.38

7.38

8.20

8.20

8.20

8.20

6.56

6.56

EXPLANATION

Line of equal depth

of possible frozen

soil during winter

Modified from Floyd (1978).

CARIBOU

AUGUSTA

CONCORD

BOSTON

NEW YORK

PHILADELPHIA

WASHINGTON

NORFOLK

ROANOKE

RALEIGH

WILMINGTON

COLUMBIA

ATLANTA

ALBANY

MACON

MIAMI

FT MEYERS

ORLANDO

GAINSVILLE

TALLAHASSEE

PENSACOLA

BILOXI

MERIDIAN

OXFORD

EL DORADO

LITTLE ROCK

FAYETTEVILLE

SPRINGFIELD

COLUMBIA

OTTUMWA

CEDAR

RAPIDS

MASON

CITY

MANKATO

DULUTH

BEMIDJI

DEVILS

LAKE

FARGO

MINOT

WILLISTON

GLENDIVE

HAVRE

MILES CITY

BILLINGS

GREAT

FALLS

HELENA

BUTTE

SALMON

LEWISTON

SPOKANE

OMAK

MISSOULA

KALISPELL

MINNEAPOLIS

DES MOINES

FORT

DODGE

JACKSON

BATON

ROUGE

CORPUS

CHRISTI

GALVESTON

SHREVEPORT

DEL RIO

AUSTIN

WACO

DALLAS

LAWTON

TULSA

WICHITA

TOPEKA

ST JOSEPH

ENID

HAYS

LINCOLN

NORFOLK

MITCHELL

PIERRE

ABERDEEN

BISMARK

LEAD

NORTH PLATTE

CHADRON

CHEYENNE

CASPER

GILLETTE

SHERIDAN

CODY

JACKSON

ROCK SPRINGS

DODGE CITY

LAMAR

DENVER

CRAIG

PUEBLO

GRAND

JUNCTION

DURANGO

ABILENE

PECOS

TUCSON

MIAMI

PHOENIX

PRESCOTT

FLAGSTAFF

KINGMAN

LAS VEGAS

ELY

AUSTIN

RENO

REDDING

LAKEVIEW

LONGVIEW

YAKIMA

SEATTLE

BEND

SALEM

BURNS

BAKER

PENDLETON

MEDFORD

ELKO

WINNEMUCCA

TONOPAH

GRAND CANYON

CEDAR CITY

SAN DIEGO

LOS

ANGELES

BAKERSFIELD

SAN FRANCISCO

SACRAMENTO

FRESNO

SAN

BERNARDINO

GREEN

RIVER

IDAHO

FALLS

TWIN

FALLS

BOISE

PROVO

LOGAN

RICHFIELD

LAS CURCES

ROSWELL

PORTALES

ALBUQUERQUE

GALLUP

SANTA FE

RATON

SILVER

CITY

LUBBOCK

AMARILLO

MONTGOMERY

BIRMINGHAM

FLORENCE

NASHVILLE

KNOXVILLE

LOUIS VILLE

DAYTON

COLUMBUS

CANTON

LIMA

KALAMAZOO

DETROIT

GRAND

RAPIDS

GRAYLING

MARQUETTE

WAUSAU

ELY

EAU CLAIRE

LA CROSSE

MADISON

CHICAGO

AURORA

PEORIA

DECATUR

MT VERNON

MARION

INDIANAPOLIS

BOWLING GREEN

LEXINGTON

CHARLESTON

ASHEVILLE

RICHMOND

ALBANY

SYRACUSE

BUFFALO

MONTPIELIER

SCRANTON

READING

ERIE

PITTSBURGH

CLARKSBURG

CLARKSBURG

CHARLESTON

Frequency of Gaging-Station Levels 17

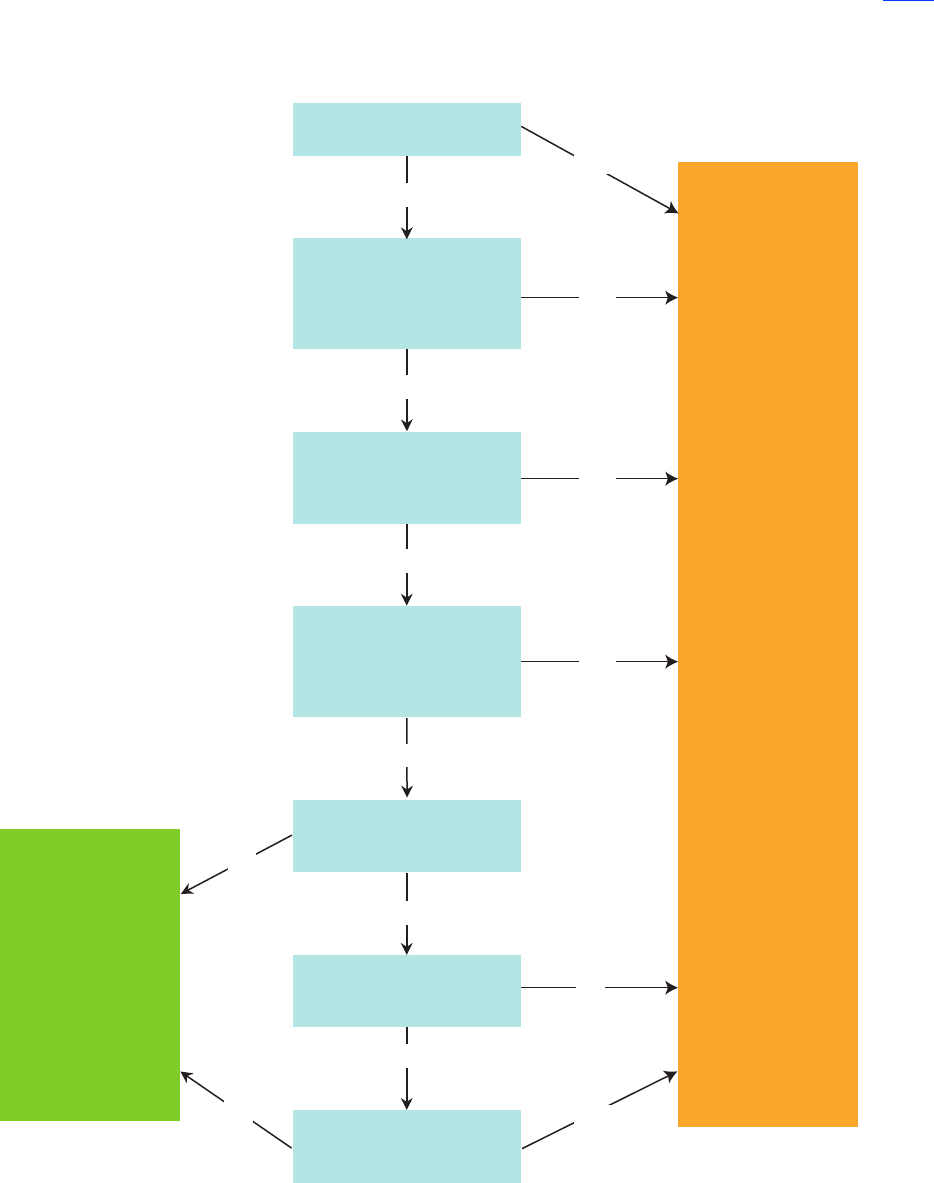

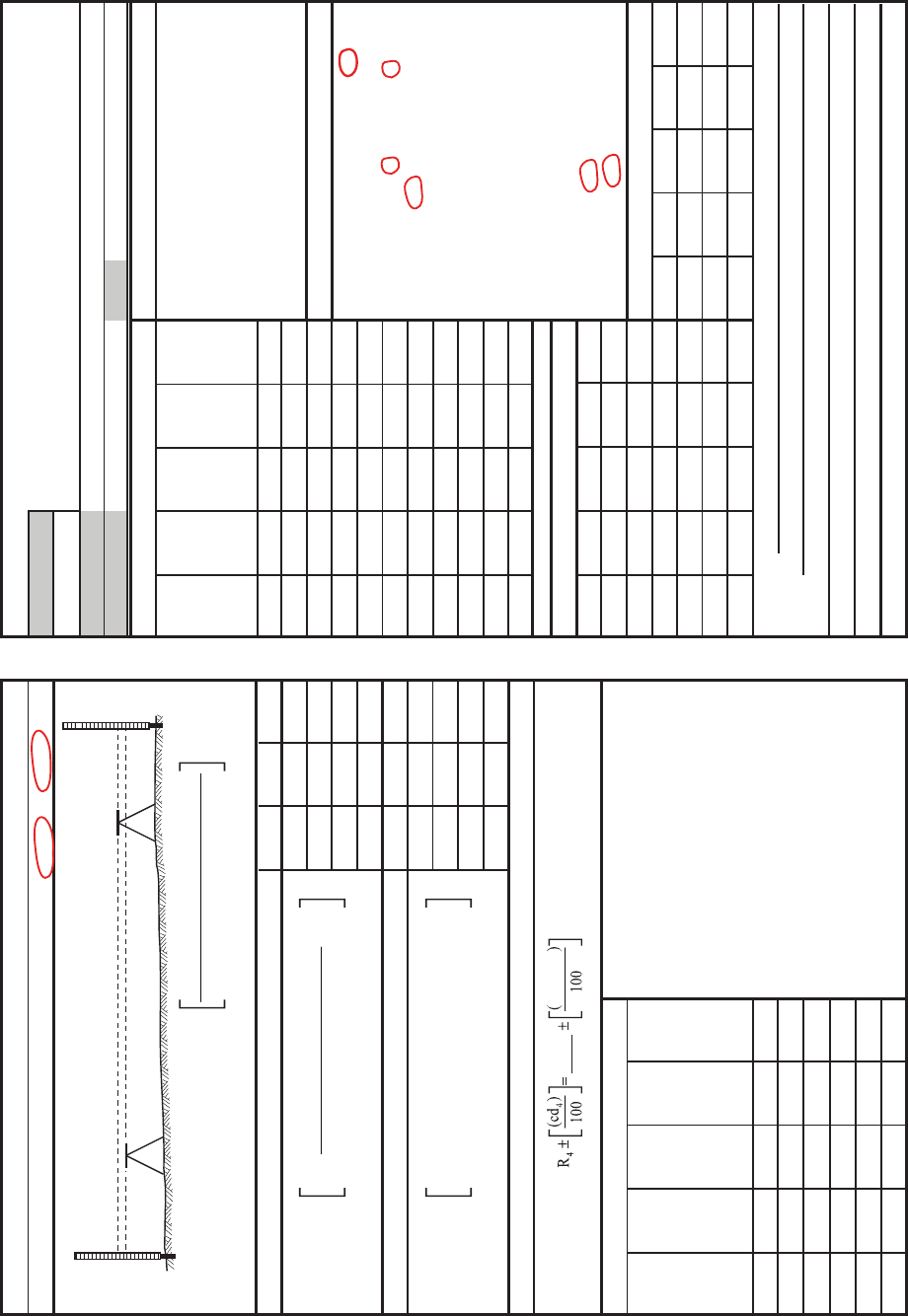

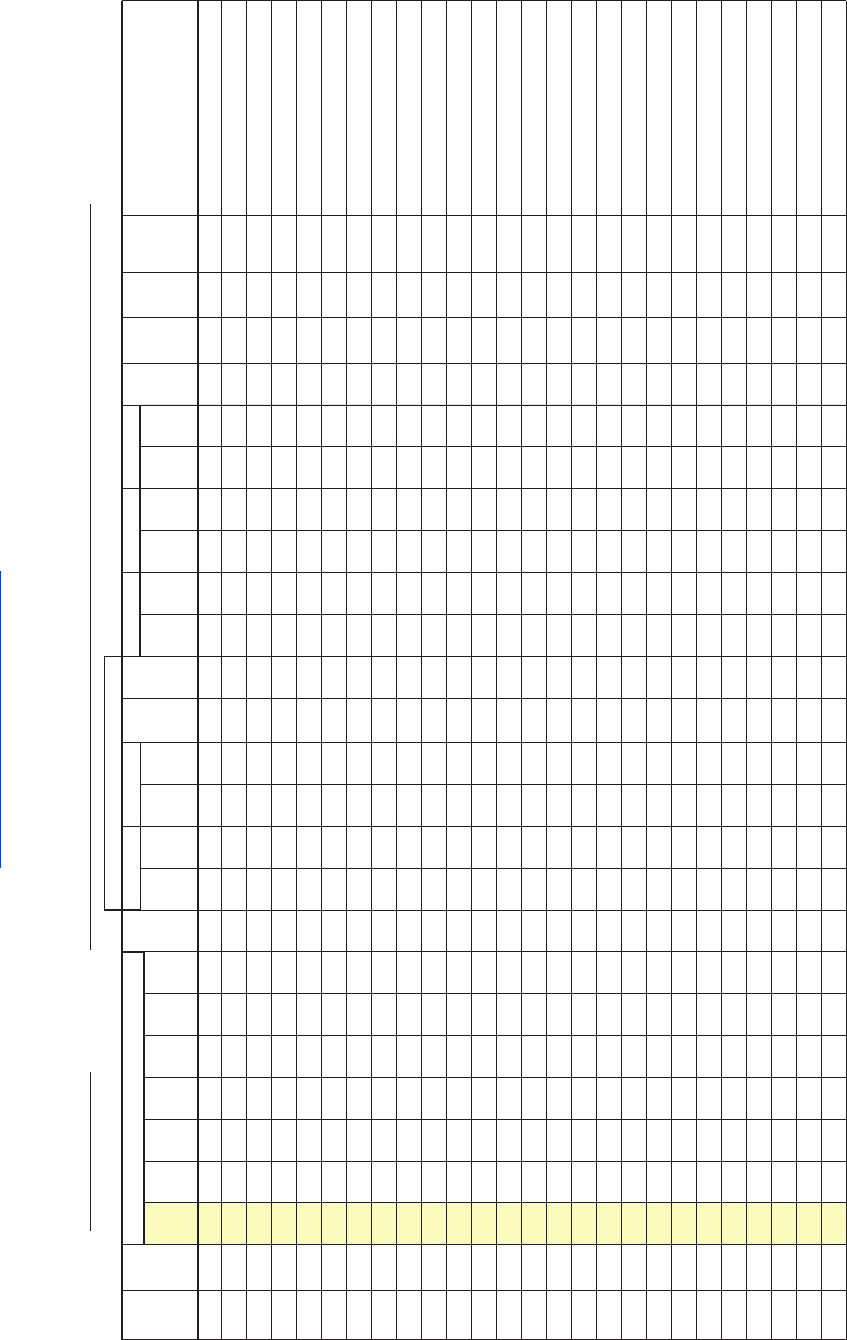

Frequency of Gaging-Station Levels

Gaging-station locations and environments vary widely

as do the factors affecting the stability of reference marks and

gages. The relative stability of a gaging station needs to be

considered when determining the frequency at which levels

should be run. For example, a station affected by ground

freezing and thawing may require levels to be run annually

in the spring, while a station with gages and reference

marks xed to bedrock that has demonstrated stability may

require levels to be run only every 5 years. Gaging-station

levels should be run frequently enough to capture any gage

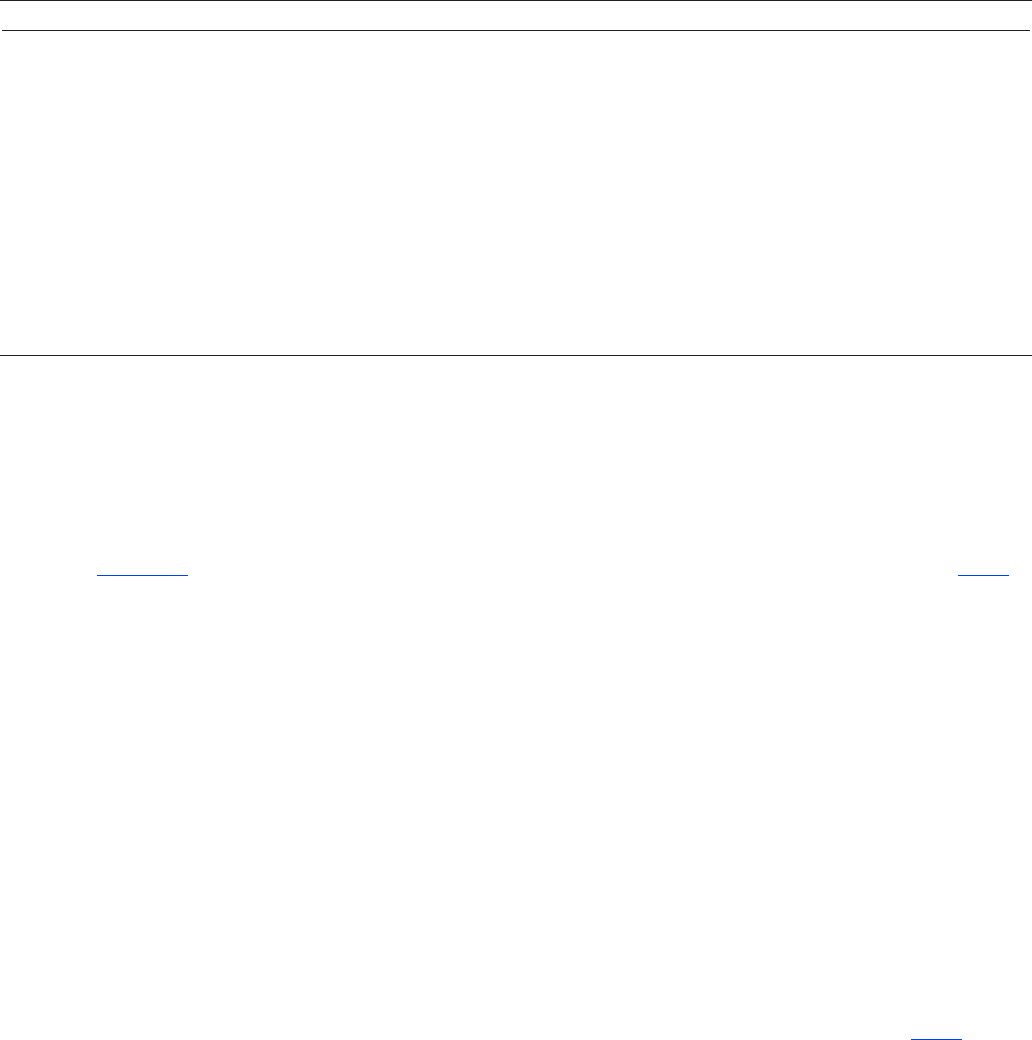

movement that may occur. A decision tree is provided (g. 14)

to help determine when levels need to be run at a gaging

station.

Are there unresolved gage

reading differences?

Has stability at the station

been demonstrated and

documented (see table 5)?

Did the level run from last year

show that the primary reference

gage elevation differs from the

gage datum enough to

require a correction?

Have more than 3 years passed

since the last complete set

of levels were run?

Are less than 3 sets of

annual levels associated with

the current reference gage?

Has an event occurred that

may have disturbed the gaging

station (flood, construction,

vandalism, other)?

Have more than 5 years passed

since the last complete set

of levels were run?

Run levels

Levels are

not needed

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

IP021599_Figure 14. Decision tree

Figure 14. Decision tree for determining if levels are needed.

18 Levels at Gaging Stations

In addition to running levels according to the site-

specic determined frequency, levels should be run whenever

a difference in gage readings cannot be resolved or damage

is suspected. Suspected damage to a gage may be associated

with ooding, ice, vandalism, nearby construction, or other

events that may disturb some part of the gaging station. A new

gage installation (including the installation of a new reference

gage at an existing station) should have three sets of annual

levels, including the initial establishment set, acquired during

the rst 3 years of operation. After the rst three sets of levels

are acquired, a level frequency of once every 3 years may be