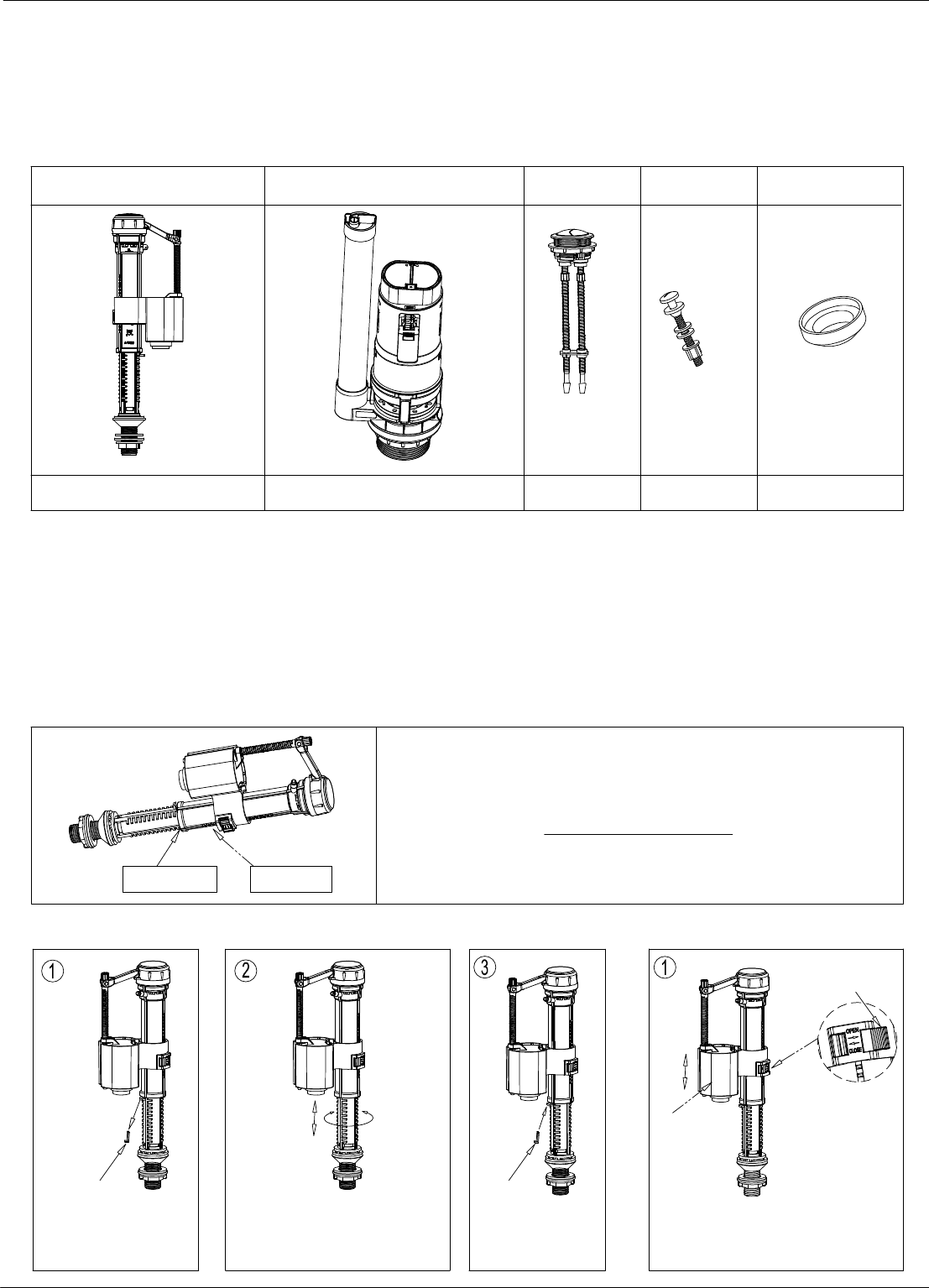

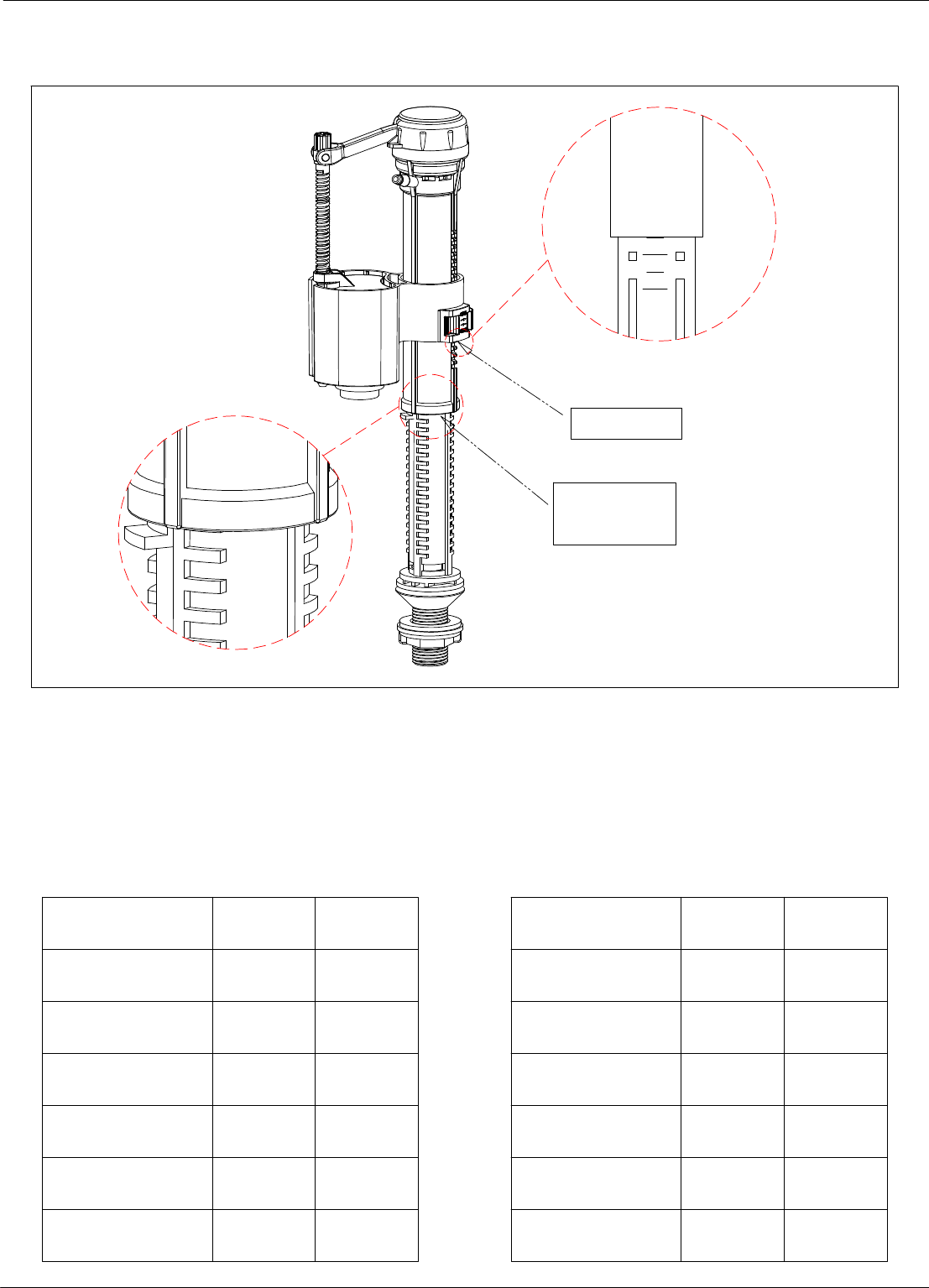

Take off locker

Locker

Locker

A: Major water level adjustment

Loosen the inlet body by

turning slightly anti-clockwise,

Adjust it up or down to correct

position and tighten clockwise.

Re-insert the locker

Slide the locker to "unlock" position,

Move the stop float up/down.

B: Minor water level adjustment

Locker

Stop

Float

F

1x 1x 1x 2x 1x

Parts Supplied:

Inlet Valve Button

1 - 7

Flush Valve

Flush Cone

"Y" scale

Note:

The Inlet Valve should be adjusted for the particular cistern into

which it is being installed.

Please refer to the Adjustment Instruction on page 5 for the

X. Y settings.

The diagrams below show the detailed adjustment method.

1: Inlet Valve scale and adjustment settings

"X" setting

Do not use bleach or bleach based cleaning products in the cistern, as these will cause damage to the seals.

We cannot be held responsible or liable for any failure which results from the use of bleach based products.

Please read these instructions carefully to avoid damage to the valves, and to ensure correct installation.

Water temperature range +2C to +45C.

Water pressure 0.2 to 8 bar.

Bolt

Installation Instruction for

Dual Flush Cistern Fittings SP697

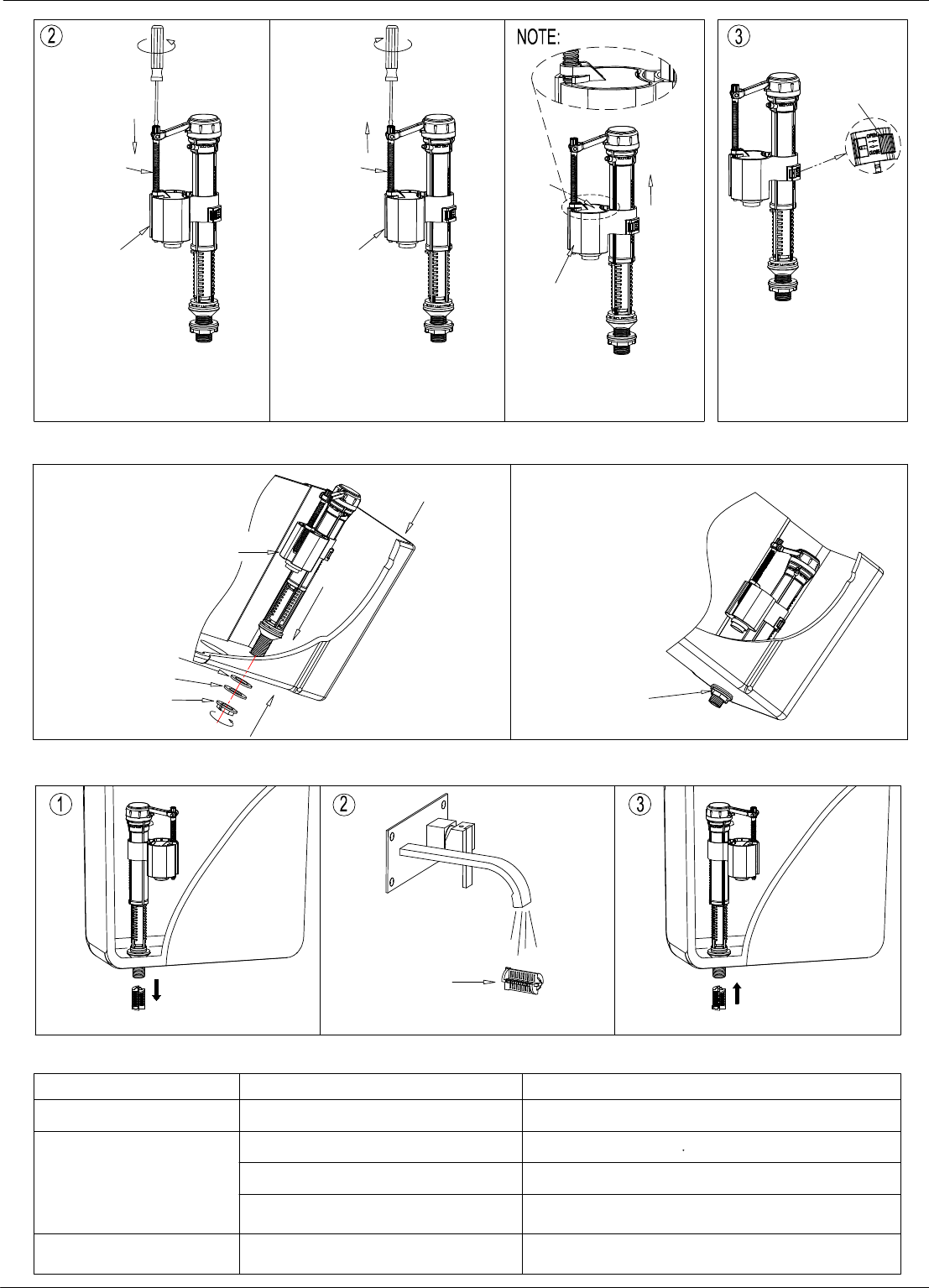

Inlet Valve Installation And Problem Solving

Leakage

Inlet Valve does not work

Clean the filter.

Tighten the nut.

The filter is blocked.

Water supply is closed.

Rubber Washer

Plastic Washer

Nut

Leakage

Incorrect water level

Problem

Solution

Open the water supply

Adjust the Water level correctly as per page 1 & 2.

Reconnect the Adjustment Rod,

and adjust the water level as per B on page 1 & 2.

The Stop Float has been over

adjusted beyond its operational range.

The Inlet Valve fixing nut

has not been tightened.

Incorrect adjustment.

Water supply is closed.

Reason

Cistern

Pull out the filter from the Inlet valve.

Filter

Insert the filter back into the Inlet valve.

4: Inlet Valve trouble shooting

2: Inlet Valve installation

Inlet Valve

3: Filter cleaning (Please clean periodically)

Clean by rinsing the filter.

Tighten the nut

2 - 7 F

Stop Float

Adjustment

Rod

Locker

To decrease the water level use

a screw driver to adjust the level

of the Stop Float ( as shown ).

The float should be lowered

To increase the water level use

a screw driver to adjust the level

of the Stop Float ( as shown ).

The float should be raised.

Slide the locker to

the "locked" position

Ensure the top surface of

Stop Float is in line with the

top surface of the Float Cup.

Stop Float

Float

cup

Stop Float

Adjustment

Rod

3 - 7 F

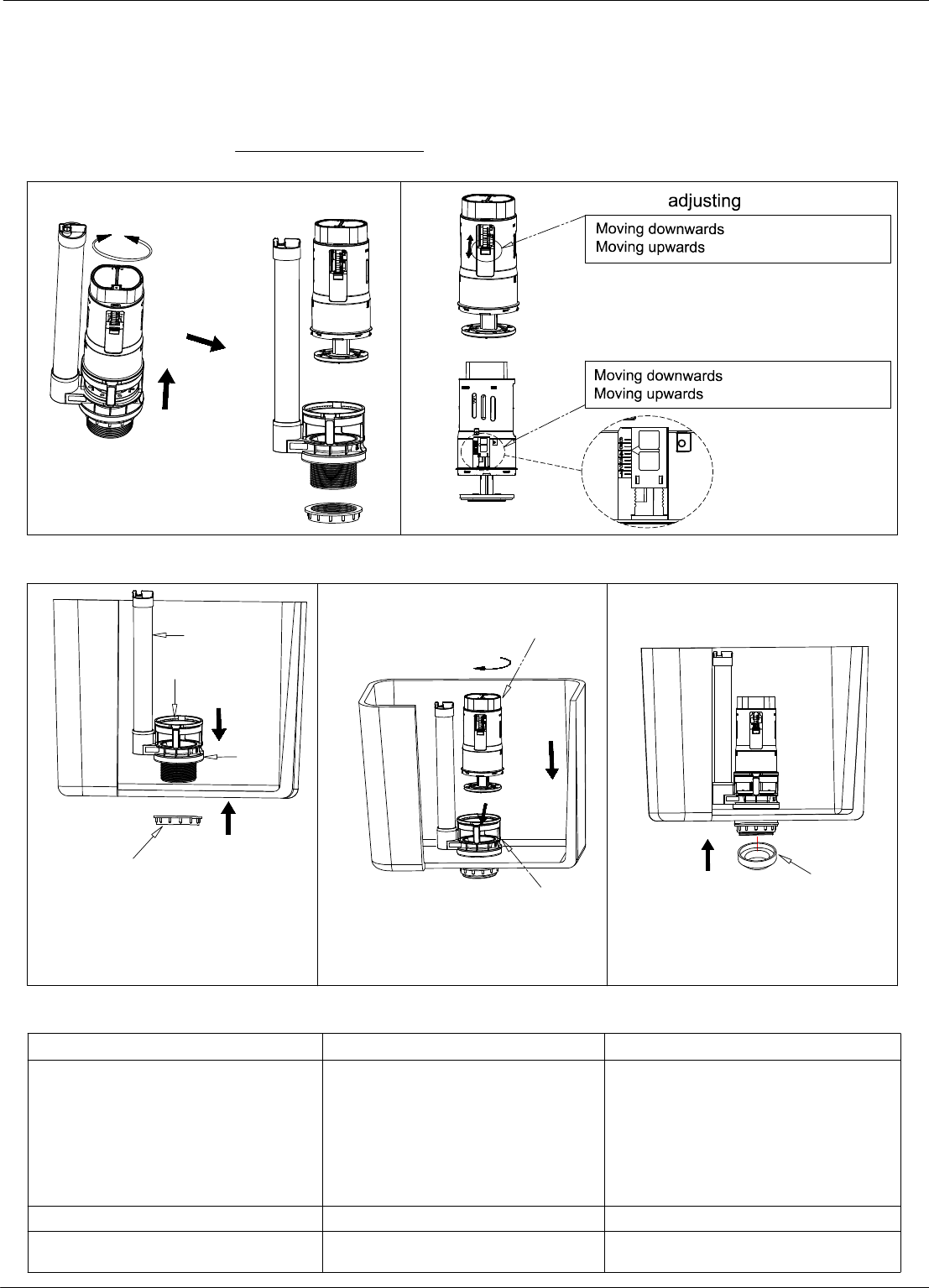

Half flush

float

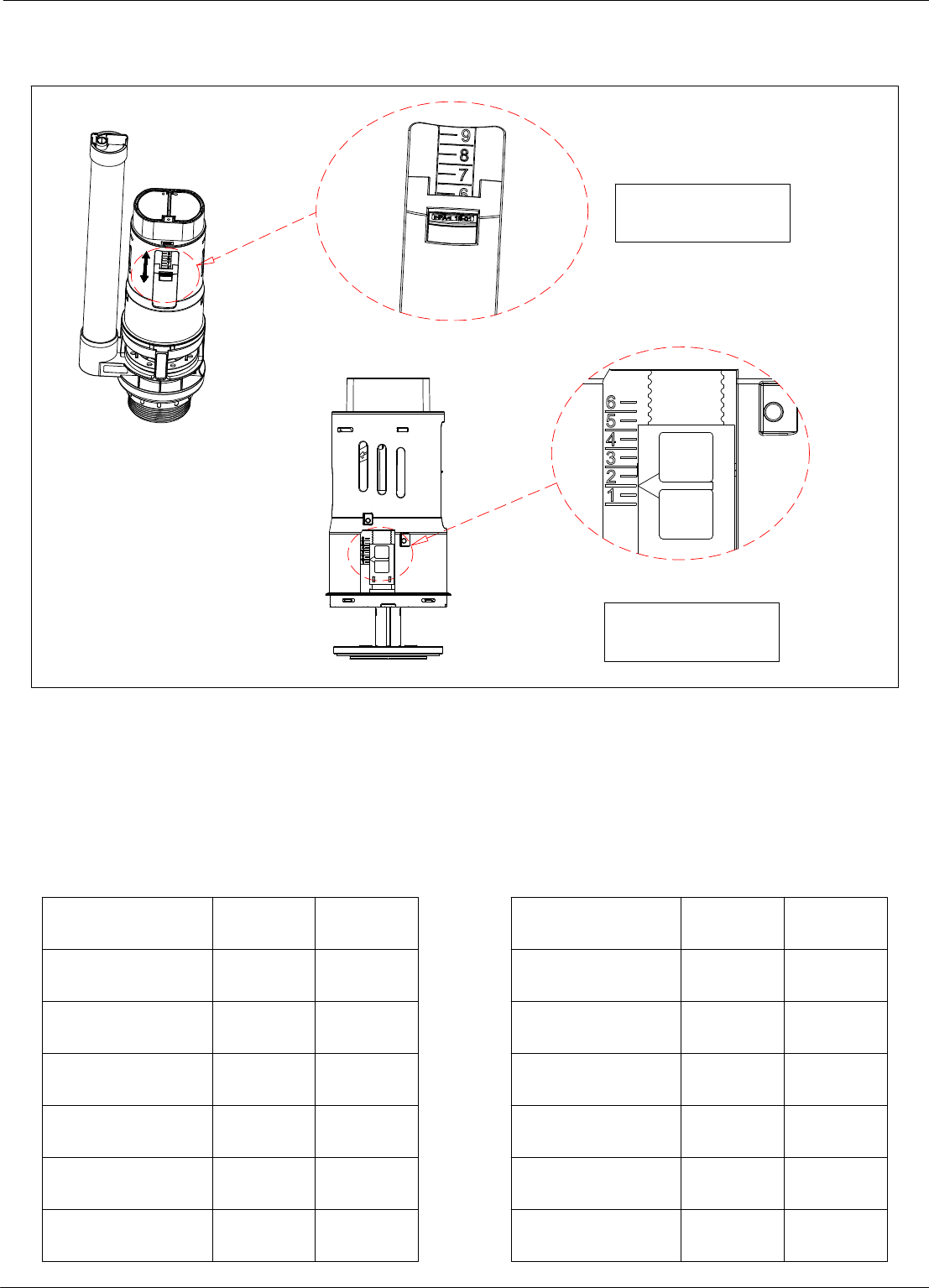

1: Flush Valve scale and adjustment setting

, flush volume increases.

, flush volume decreases.

3: Flush Valve trouble shooting

1.Install again according to the correct

installation procedure.

4.Take off and wash flush valve body.

Adjust the full flush adjustor or the half

flush float cup.

Full flush or half flush water level is

too high or too low.

Water level is adjusted incorrectly.

Push rod is too short.

4.Flush valve body is stuck.

3.Flush valve seat does not fit on the

flush valve body.

1.Incorrect installation.

No flush, low flush or half flush volume

Problem

Leakage

3.Install again, ensuring both surfaces

are clean for a water tight seal.

Reason Solution

Adjust the push rod length. (see page 4)

2: Flush Valve installation

Note: The Flush Valve should be adjusted for the particular cistern into which it is being installed.

Please refer to the Adjustment Instruction on page 6 for the full flush and half flush settings.

The diagrams below show the detailed adjustment method.

Flush Valve Installation And Problem Solving

Overflow pipe

Full flush adjustor

, flush volume increases.

, flush volume decreases.

Insert flush valve seat attached with

rubber washer into cistern flush hole.

Then install and tighten with the

fixing nut.

Flush valve seat

Rubber

washer

Fixing nut

Flush valve

body

Flush valve

seat

Push the flush cone over the fixing nut,

ensure that it is flat, and there will be no

leakage between cistern and pan.

2.The push rod is too long causing a

gap between the washer and the seat.

2.Adjust the push rod length.

(see page 4)

Flush cone

4 - 7 F

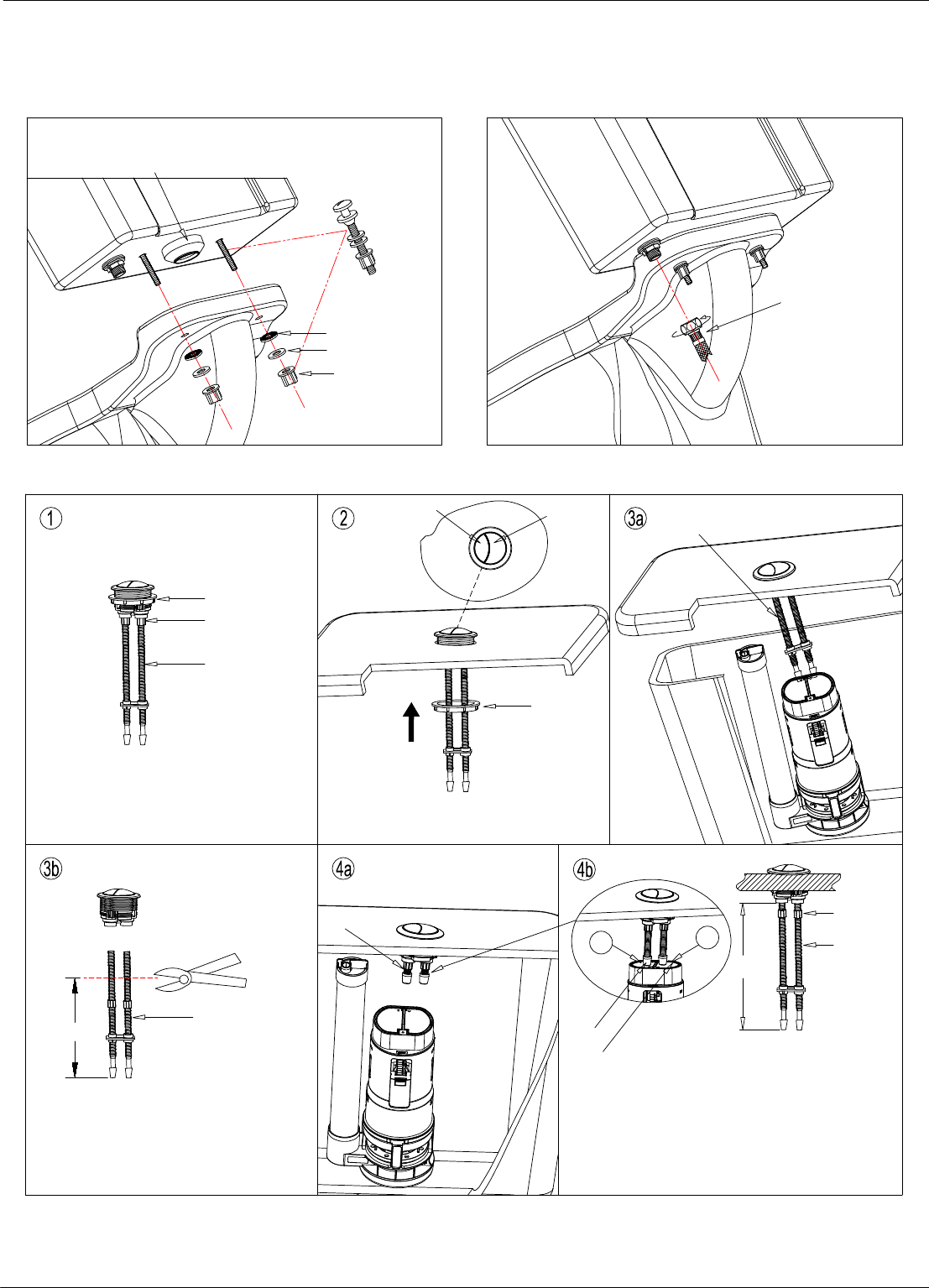

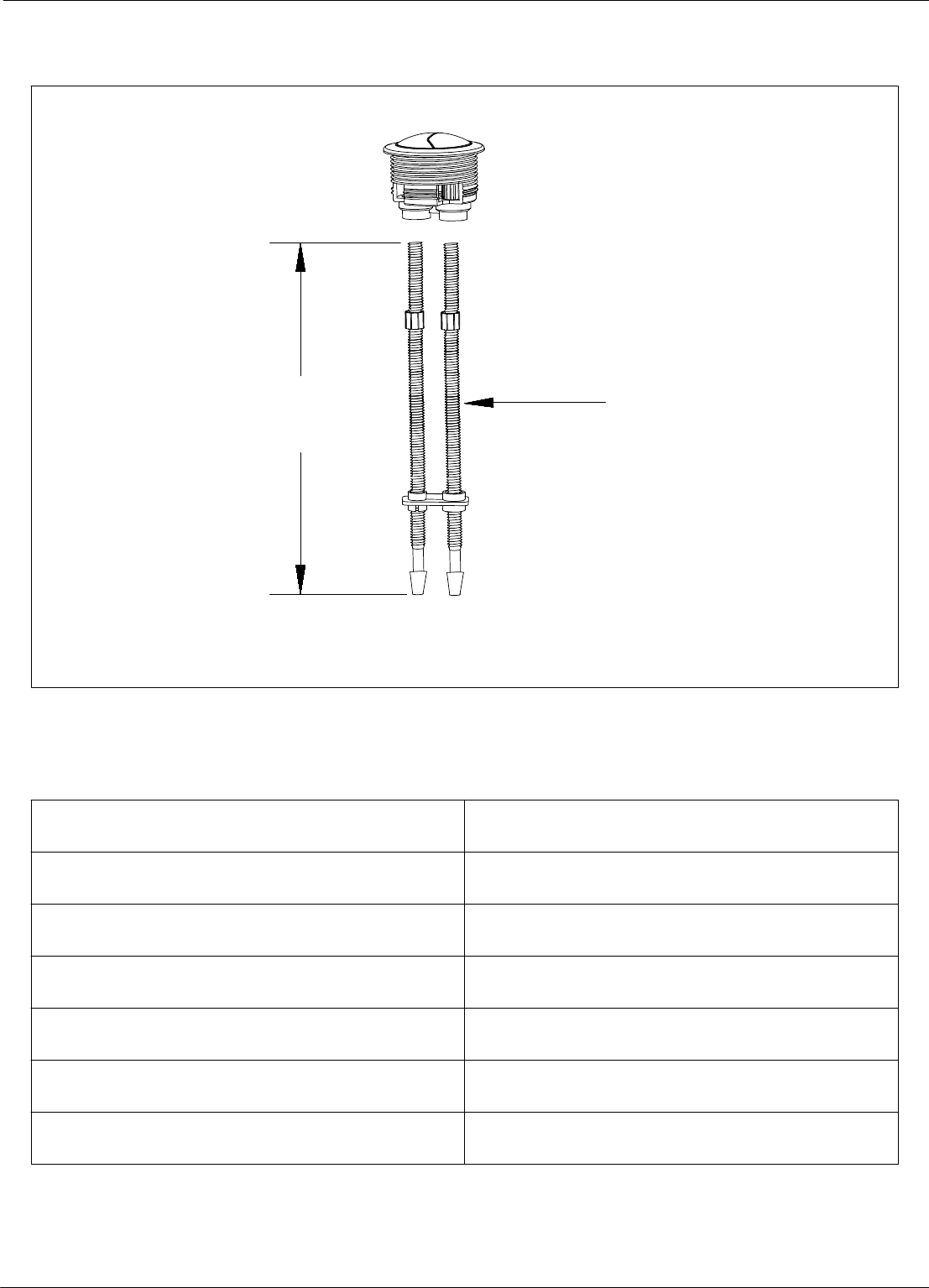

Cistern and Flush Button Installation

1: Install Close Coupled Cistern To Pan 2: Connect the water supply to the cistern

3: Install The Flush Button

Fixing nut

Lock nut

Take off the fixing nut.

Screw the lock nut to position.

Install the dual flush button onto the

cistern lid, and tighten the fixing nut.

Push rod

Push rod

Fixing nut

Lock nut

Push rod

A

Adjust the length of

A

by turning the push rod, and

remember to tighten the lock nut after finishing the

adjustment of the push rod

(A).

The final position should be that push rods just

come into contact with the flush valve, but should

not push down onto it unless the button is activated.

Loosen the lock nuts, and unscrew the

push rods to cut off the redundant section.

Please refer to the recommended length

"Z " of push rods for particular cistern on

page 7

.

Too long

Too short

4: After installation check that the full flush and half flush are working correctly.

Please consult the trouble shooting pages if there are any problems.

Half flush

Full flush

B

C

Full Flush Button - White

Z

Half Flush Button - Blue

Water supply

Fixing nut

Plastic washer

Rubber washer

* Please ensure the flush cone is in position before

installation. A thin bead of silicone should be applied

to the flush cone and the inlet hole of pan if necessary.

F

"Y" scale

Exposed

"X" steps

2

0

5 - 7

Note:

The above diagram is for reference only. In this example, X is set to 17 and Y is set to 3.

The inlet valve can be adjusted to suit the particular cistern, please refer to below tables for

the settings.

For adjustment method, please refer to the installation instruction on page 1 & 2.

Inlet Valve Adjustment Instructions

For 6L full flush and 3L half flush

Cistern code X Y

CC.1036 17 3

CM0007 20 3

15.B.27353 19 2

15.B.27349 17 2

SPH002 21 1

MAR.006 21 0

For 4.5L full flush and 2.6L half flush

Cistern code X Y

CC.1036 13 3

CM0007 17 3

15.B.27353 14 2

15.B.27349 16 2

SPH002 19 1

MAR.006 19 0

F6 - 7

Note:

The above diagram is for reference only. In this example, A is set to 6.5 and B is set to 2.

The flush valve can be adjusted to suit the particular cistern, please refer to below tables for

the settings.

For adjustment method, please refer to the installation instruction on page 3.

Flush Valve Adjustment Instructions

For 6L full flush and 3L half flush

Cistern code A B

CC.1036

6.5 2

CM0007 6.5 1.5

15.B.27353 7.5 1.5

15.B.27349

7

1.5

SPH002 7 1

MAR.006

7

1.5

For 4.5L full flush and 2.6L half flush

Cistern code A B

CC.1036 4.5 5

CM0007

6.5 5

15.B.27353 3.5 2

15.B.27349 3.5

4

SPH002

7

5

MAR.006

6

5

Half flush float

Should be set on

the "A" mark

Full flush adjustor

Should be set on

the "B" setting

F7 - 7

Recommended length of push rods

The push rods can be cut off to suit the particular cistern, please refer to below

table for the Z value.

Cistern code Z (mm)

CC.1036

CM0007

15.B.27353

15.B.27349

SPH002

MAR.006

Push rod

Z

197

197

159

207

181

200